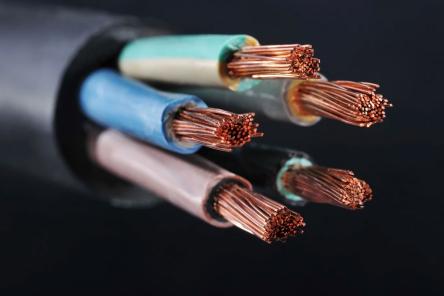

When it comes to choosing the right type of copper wire for your electrical or mechanical projects, there are a number of important factors to consider. One of the key properties that engineers and designers look at when selecting a wire material is the Young’s Modulus, also known as the modulus of elasticity. In this article, we will explore the importance of the Young’s Modulus in relation to 36 SWG copper wire, and why it is a crucial parameter to consider when working with this material. 36 SWG copper wire is a popular choice for a wide range of applications due to its excellent conductivity, malleability, and corrosion resistance.

.

However, the mechanical properties of the wire, including its Young’s Modulus, play a significant role in determining its performance in various settings. The Young’s Modulus of a material is a measure of its stiffness – it indicates how much a material will deform under a given amount of stress. In simpler terms, it is a measure of the material’s ability to withstand stretching or compression without permanent deformation. The Young’s Modulus of copper is approximately 120-130 GPa, which is significantly higher than many other materials commonly used for wiring applications. This high modulus means that copper wire is relatively stiff and has a low elasticity compared to materials like aluminum or steel. For 36 SWG copper wire specifically, the Young’s Modulus plays a crucial role in determining how the wire will behave under different loads and stresses. When designing electrical or mechanical systems that utilize 36 SWG copper wire, understanding the Young’s Modulus of the material is essential for ensuring the overall performance and reliability of the system. For example, in applications where the wire is subjected to tensile or compressive forces, knowledge of the Young’s Modulus can help engineers calculate the amount of deformation the wire will experience and design the system accordingly to prevent failure or damage. In addition to its mechanical properties, the Young’s Modulus of 36 SWG copper wire also influences its electrical performance. The stiffness of the wire affects its ability to maintain a consistent shape and electrical conductivity under varying conditions.

However, the mechanical properties of the wire, including its Young’s Modulus, play a significant role in determining its performance in various settings. The Young’s Modulus of a material is a measure of its stiffness – it indicates how much a material will deform under a given amount of stress. In simpler terms, it is a measure of the material’s ability to withstand stretching or compression without permanent deformation. The Young’s Modulus of copper is approximately 120-130 GPa, which is significantly higher than many other materials commonly used for wiring applications. This high modulus means that copper wire is relatively stiff and has a low elasticity compared to materials like aluminum or steel. For 36 SWG copper wire specifically, the Young’s Modulus plays a crucial role in determining how the wire will behave under different loads and stresses. When designing electrical or mechanical systems that utilize 36 SWG copper wire, understanding the Young’s Modulus of the material is essential for ensuring the overall performance and reliability of the system. For example, in applications where the wire is subjected to tensile or compressive forces, knowledge of the Young’s Modulus can help engineers calculate the amount of deformation the wire will experience and design the system accordingly to prevent failure or damage. In addition to its mechanical properties, the Young’s Modulus of 36 SWG copper wire also influences its electrical performance. The stiffness of the wire affects its ability to maintain a consistent shape and electrical conductivity under varying conditions.

..

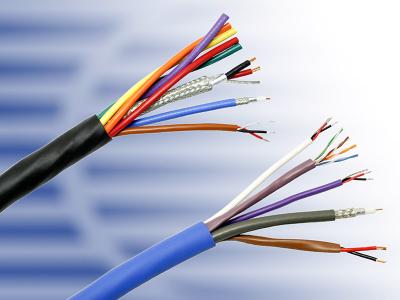

A wire with a high Young’s Modulus will have better dimensional stability, which is important for maintaining a reliable electrical connection over time. Another important aspect to consider when working with 36 SWG copper wire is its resistance to fatigue failure. Fatigue failure can occur when a material is subjected to repeated loading and unloading cycles, causing it to weaken and eventually fail. The Young’s Modulus of the wire plays a key role in determining its resistance to fatigue failure, as materials with higher moduli are generally more resistant to this type of damage. In industrial and engineering applications, where reliability and longevity are critical factors, choosing a material with the right mechanical properties is essential. 36 SWG copper wire, with its high Young’s Modulus and excellent conductivity, is a versatile choice for a wide range of projects. Whether you are designing electrical circuits, constructing machinery, or building prototypes, understanding the Young’s Modulus of copper wire can help you make informed decisions about the materials you use. In conclusion, the Young’s Modulus of 36 SWG copper wire is a key parameter that influences its mechanical and electrical properties, making it an important consideration for engineers and designers working on a variety of projects. By understanding the significance of this property and how it affects the performance of the wire, you can make informed decisions about the materials you use and ensure the success of your projects. Whether you are working on a small DIY project or a large-scale industrial application, the choice of materials can have a significant impact on the overall performance and durability of your design. When it comes to 36 SWG copper wire, being aware of its Young’s Modulus can help you optimize your designs for maximum efficiency and reliability. In applications where the wire is expected to undergo bending or twisting, the Young’s Modulus of 36 SWG copper wire becomes particularly important. The stiffness of the material will determine how much it can flex before experiencing plastic deformation, which can lead to permanent damage. By selecting a material with the appropriate Young’s Modulus, you can ensure that the wire will maintain its shape and integrity under the expected loading conditions.

A wire with a high Young’s Modulus will have better dimensional stability, which is important for maintaining a reliable electrical connection over time. Another important aspect to consider when working with 36 SWG copper wire is its resistance to fatigue failure. Fatigue failure can occur when a material is subjected to repeated loading and unloading cycles, causing it to weaken and eventually fail. The Young’s Modulus of the wire plays a key role in determining its resistance to fatigue failure, as materials with higher moduli are generally more resistant to this type of damage. In industrial and engineering applications, where reliability and longevity are critical factors, choosing a material with the right mechanical properties is essential. 36 SWG copper wire, with its high Young’s Modulus and excellent conductivity, is a versatile choice for a wide range of projects. Whether you are designing electrical circuits, constructing machinery, or building prototypes, understanding the Young’s Modulus of copper wire can help you make informed decisions about the materials you use. In conclusion, the Young’s Modulus of 36 SWG copper wire is a key parameter that influences its mechanical and electrical properties, making it an important consideration for engineers and designers working on a variety of projects. By understanding the significance of this property and how it affects the performance of the wire, you can make informed decisions about the materials you use and ensure the success of your projects. Whether you are working on a small DIY project or a large-scale industrial application, the choice of materials can have a significant impact on the overall performance and durability of your design. When it comes to 36 SWG copper wire, being aware of its Young’s Modulus can help you optimize your designs for maximum efficiency and reliability. In applications where the wire is expected to undergo bending or twisting, the Young’s Modulus of 36 SWG copper wire becomes particularly important. The stiffness of the material will determine how much it can flex before experiencing plastic deformation, which can lead to permanent damage. By selecting a material with the appropriate Young’s Modulus, you can ensure that the wire will maintain its shape and integrity under the expected loading conditions.

…

Furthermore, the Young’s Modulus of 36 SWG copper wire also influences its response to temperature changes. Copper is known for its excellent thermal conductivity, but its modulus of elasticity can affect how the wire expands and contracts with temperature variations. Understanding this property can help you design systems that can accommodate thermal expansion without causing stress or strain on the wire, leading to improved longevity and performance. When it comes to selecting the right type of wire for your project, it is essential to consider not only the electrical properties but also the mechanical characteristics of the material. The Young’s Modulus of 36 SWG copper wire provides valuable information about its stiffness, elasticity, and overall behavior under different conditions. By taking this parameter into account during the design phase, you can ensure that your project will meet its functional requirements and deliver reliable performance over time. In conclusion, the Young’s Modulus of 36 SWG copper wire is a critical parameter that influences its mechanical and electrical properties, making it an important consideration for a wide range of applications. Whether you are working on a simple wiring task or a complex engineering project, understanding how this property impacts the performance of the wire can help you make informed decisions and achieve the desired outcomes. By leveraging the knowledge of the Young’s Modulus of 36 SWG copper wire, you can design systems that are optimized for efficiency, reliability, and longevity. This versatile material offers exceptional conductivity and corrosion resistance, making it a preferred choice for many applications. By factoring in its mechanical properties, including the Young’s Modulus, you can ensure that your projects are built to last and perform at their best. In conclusion, the Young’s Modulus of 36 SWG copper wire is a fundamental property that influences its behavior in various applications, from electrical circuits to mechanical components. By understanding how this parameter affects the wire’s stiffness, elasticity, and response to different loads, you can make informed decisions about the materials you use and design systems that are reliable, efficient, and durable.

Furthermore, the Young’s Modulus of 36 SWG copper wire also influences its response to temperature changes. Copper is known for its excellent thermal conductivity, but its modulus of elasticity can affect how the wire expands and contracts with temperature variations. Understanding this property can help you design systems that can accommodate thermal expansion without causing stress or strain on the wire, leading to improved longevity and performance. When it comes to selecting the right type of wire for your project, it is essential to consider not only the electrical properties but also the mechanical characteristics of the material. The Young’s Modulus of 36 SWG copper wire provides valuable information about its stiffness, elasticity, and overall behavior under different conditions. By taking this parameter into account during the design phase, you can ensure that your project will meet its functional requirements and deliver reliable performance over time. In conclusion, the Young’s Modulus of 36 SWG copper wire is a critical parameter that influences its mechanical and electrical properties, making it an important consideration for a wide range of applications. Whether you are working on a simple wiring task or a complex engineering project, understanding how this property impacts the performance of the wire can help you make informed decisions and achieve the desired outcomes. By leveraging the knowledge of the Young’s Modulus of 36 SWG copper wire, you can design systems that are optimized for efficiency, reliability, and longevity. This versatile material offers exceptional conductivity and corrosion resistance, making it a preferred choice for many applications. By factoring in its mechanical properties, including the Young’s Modulus, you can ensure that your projects are built to last and perform at their best. In conclusion, the Young’s Modulus of 36 SWG copper wire is a fundamental property that influences its behavior in various applications, from electrical circuits to mechanical components. By understanding how this parameter affects the wire’s stiffness, elasticity, and response to different loads, you can make informed decisions about the materials you use and design systems that are reliable, efficient, and durable.

Your comment submitted.