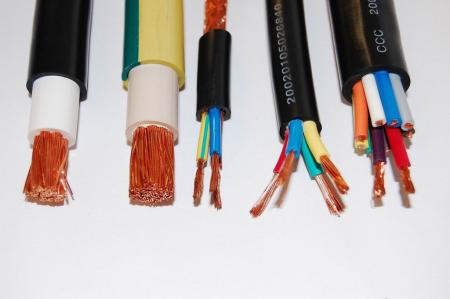

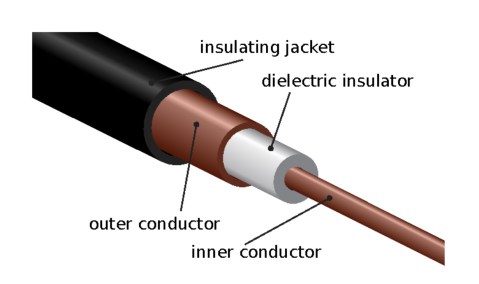

Soldering copper wire is a fundamental technique that is essential for a wide range of DIY projects, repairs, and electrical work. Whether you are a seasoned professional or a beginner looking to expand your skill set, mastering the art of soldering copper wire will open up a world of possibilities and empower you to tackle a wide range of tasks with confidence. In this comprehensive guide, we will take you through everything you need to know to solder copper wire like a pro. From understanding the basics of soldering to selecting the right tools and materials, to mastering the techniques that will ensure a strong and reliable connection, we’ve got you covered. Why Soldering Copper Wire is Important Before we dive into the nitty-gritty of soldering copper wire, it’s important to understand why this skill is so crucial. Copper wire is a common material used in electrical work, circuitry, and various DIY projects because of its excellent conductivity and resilience. When two pieces of copper wire need to be joined together, soldering provides a reliable and durable connection that ensures the electrical current can flow smoothly and without interruption. Soldering creates a strong bond between the wires that is resistant to vibrations, temperature fluctuations, and corrosion, making it a preferred method for securing connections in a wide range of applications. Whether you are repairing a broken wire, building a circuit board, or creating custom jewelry, the ability to solder copper wire effectively is a valuable skill that will serve you well in numerous projects. Understanding the Basics of Soldering Soldering is the process of joining two metal surfaces together using a filler material called solder. Solder is typically a metal alloy with a low melting point that can be melted to form a bond between the surfaces being joined. When it cools, the solder solidifies and creates a strong, conductive connection between the two pieces. For soldering copper wire, it’s important to select the right type of solder that is compatible with copper, such as a lead-free rosin-core solder. The rosin flux core helps clean and prepare the surfaces for soldering, ensuring a strong bond. Additionally, you will need a soldering iron or soldering gun to heat the solder and apply it to the wires. Selecting the Right Tools and Materials Before you begin soldering copper wire, it’s essential to gather all the necessary tools and materials to ensure a successful outcome. Here are the key items you will need: 1. Soldering Iron or Soldering Gun: This is the tool used to heat the solder and apply it to the copper wire. Make sure to select a soldering iron with an appropriate wattage for the size of the wire you are working with. 2. Solder: Choose a high-quality solder that is designed for use with copper wire. Lead-free solder is recommended for health and safety reasons, especially if you will be handling the solder frequently. 3. Flux: Flux is a chemical agent that cleans and prepares the surfaces to be soldered, promoting better adhesion between the solder and the metal. Rosin-core solder contains flux, but additional flux may be needed for larger wires or heavily oxidized surfaces. 4. Wire Strippers: To prepare the copper wire for soldering, you will need wire strippers to remove the insulation and expose the bare metal. 5. Helping Hands: These are devices that hold the wires in place during soldering, keeping them steady and ensuring a clean connection. 6. Soldering Stand: A soldering stand or holder keeps the soldering iron safely stored when not in use, preventing accidents and burns. Mastering the Techniques of Soldering Copper Wire Now that you have gathered your tools and materials, it’s time to dive into the techniques of soldering copper wire. Follow these steps to achieve a strong and reliable connection: 1. Prepare the Wires: Start by stripping the insulation from the ends of the copper wires to expose a clean, bare metal surface. Use wire strippers to remove the insulation carefully, being mindful not to damage the wire itself. 2. Tinning the Wires: Tinning is the process of applying a thin coat of solder to the exposed wire ends to help facilitate the soldering process. Heat the wire with the soldering iron and apply a small amount of solder to the heated area. The solder should flow smoothly and evenly along the wire, creating a shiny coating. 3. Twist the Wires Together: If you are joining two wires together, twist the tinned ends of the wires tightly to create a secure connection. The twisted wires should be neat and compact to ensure a strong bond.

.

4. Apply Flux: If additional flux is needed, apply a small amount to the twisted wire connection to help clean and prepare the surfaces for soldering. Flux promotes better adhesion between the solder and the metal and helps prevent oxidation during the heating process. 5. Soldering the Connection: Heat the twisted wire connection with the soldering iron until it reaches the desired temperature. Touch the solder to the heated area, allowing it to flow and create a solid bond between the wires. Be sure to apply just enough solder to cover the connection without creating excess buildup. 6. Let it Cool: Once you have soldered the connection, allow it to cool and solidify before handling it. Do not disturb the connection while it is cooling, as this could weaken the bond and compromise the integrity of the joint. 7. Insulate the Connection: After the soldered connection has cooled, insulate it with heat shrink tubing or electrical tape to protect it from moisture, dust, and physical damage. Proper insulation ensures the longevity and reliability of the soldered joint. Troubleshooting Common Soldering Issues While soldering copper wire is a relatively straightforward process, there are some common issues that you may encounter along the way. Here are a few tips for troubleshooting common soldering problems: 1. Cold Joints: A cold joint occurs when the solder does not flow properly and creates a weak or unreliable connection. To avoid cold joints, make sure the soldering iron is hot enough to melt the solder smoothly and evenly. Also, ensure that the surfaces are clean and properly tinned before soldering. 2. Excessive Solder: Applying too much solder can lead to excess buildup, which can create a messy connection and potentially cause short circuits. To avoid excessive solder, use a minimal amount and allow it to flow naturally along the wire connection.

4. Apply Flux: If additional flux is needed, apply a small amount to the twisted wire connection to help clean and prepare the surfaces for soldering. Flux promotes better adhesion between the solder and the metal and helps prevent oxidation during the heating process. 5. Soldering the Connection: Heat the twisted wire connection with the soldering iron until it reaches the desired temperature. Touch the solder to the heated area, allowing it to flow and create a solid bond between the wires. Be sure to apply just enough solder to cover the connection without creating excess buildup. 6. Let it Cool: Once you have soldered the connection, allow it to cool and solidify before handling it. Do not disturb the connection while it is cooling, as this could weaken the bond and compromise the integrity of the joint. 7. Insulate the Connection: After the soldered connection has cooled, insulate it with heat shrink tubing or electrical tape to protect it from moisture, dust, and physical damage. Proper insulation ensures the longevity and reliability of the soldered joint. Troubleshooting Common Soldering Issues While soldering copper wire is a relatively straightforward process, there are some common issues that you may encounter along the way. Here are a few tips for troubleshooting common soldering problems: 1. Cold Joints: A cold joint occurs when the solder does not flow properly and creates a weak or unreliable connection. To avoid cold joints, make sure the soldering iron is hot enough to melt the solder smoothly and evenly. Also, ensure that the surfaces are clean and properly tinned before soldering. 2. Excessive Solder: Applying too much solder can lead to excess buildup, which can create a messy connection and potentially cause short circuits. To avoid excessive solder, use a minimal amount and allow it to flow naturally along the wire connection.

..

3. Oxidation: Oxidation occurs when the metal surfaces are exposed to air and moisture, leading to a dull or tarnished appearance. To prevent oxidation, use flux to clean and prepare the surfaces before soldering, and work quickly to complete the solder joint before oxidation occurs. 4. Solder Bridges: Solder bridges happen when solder flows between two adjacent connections, creating a short circuit. To avoid solder bridges, work carefully and methodically, ensuring that the solder flows only where it is needed and does not create unintended connections. 5. Weak Connections: Weak connections can result from insufficient heat, improper surface preparation, or inadequate solder coverage. To create strong and reliable connections, make sure to heat the wire sufficiently, clean and tin the surfaces properly, and apply enough solder to cover the joint completely. By following these tips and techniques, you will be well on your way to mastering the art of soldering copper wire. With practice and patience, you can develop this essential skill and tackle a wide range of projects with confidence and precision. Conclusion Soldering copper wire is a valuable skill that opens up a world of possibilities for DIY enthusiasts, hobbyists, and professionals alike. By mastering the techniques of soldering and understanding the importance of creating strong and reliable connections, you can tackle a wide range of projects with confidence and precision. From repairing electrical wiring to building custom electronics, soldering copper wire is an essential technique that empowers you to bring your ideas to life and create functional and durable connections that stand the test of time. With the right tools, materials, and techniques, you can solder copper wire like a pro and take your projects to the next level. So, whether you are a beginner looking to expand your skills or a seasoned pro seeking to hone your craft, mastering the art of soldering copper wire will equip you with the knowledge and expertise needed to succeed in a wide range of DIY endeavors. Start practicing today, and soon you’ll be soldering copper wire with confidence and precision like never before. The ability to solder copper wire effectively is not only a valuable skill but also a gateway to a world of creativity and innovation. Whether you are a hobbyist, maker, or professional electrician, mastering this fundamental technique will equip you with the confidence and capability to tackle a variety of projects with ease.

3. Oxidation: Oxidation occurs when the metal surfaces are exposed to air and moisture, leading to a dull or tarnished appearance. To prevent oxidation, use flux to clean and prepare the surfaces before soldering, and work quickly to complete the solder joint before oxidation occurs. 4. Solder Bridges: Solder bridges happen when solder flows between two adjacent connections, creating a short circuit. To avoid solder bridges, work carefully and methodically, ensuring that the solder flows only where it is needed and does not create unintended connections. 5. Weak Connections: Weak connections can result from insufficient heat, improper surface preparation, or inadequate solder coverage. To create strong and reliable connections, make sure to heat the wire sufficiently, clean and tin the surfaces properly, and apply enough solder to cover the joint completely. By following these tips and techniques, you will be well on your way to mastering the art of soldering copper wire. With practice and patience, you can develop this essential skill and tackle a wide range of projects with confidence and precision. Conclusion Soldering copper wire is a valuable skill that opens up a world of possibilities for DIY enthusiasts, hobbyists, and professionals alike. By mastering the techniques of soldering and understanding the importance of creating strong and reliable connections, you can tackle a wide range of projects with confidence and precision. From repairing electrical wiring to building custom electronics, soldering copper wire is an essential technique that empowers you to bring your ideas to life and create functional and durable connections that stand the test of time. With the right tools, materials, and techniques, you can solder copper wire like a pro and take your projects to the next level. So, whether you are a beginner looking to expand your skills or a seasoned pro seeking to hone your craft, mastering the art of soldering copper wire will equip you with the knowledge and expertise needed to succeed in a wide range of DIY endeavors. Start practicing today, and soon you’ll be soldering copper wire with confidence and precision like never before. The ability to solder copper wire effectively is not only a valuable skill but also a gateway to a world of creativity and innovation. Whether you are a hobbyist, maker, or professional electrician, mastering this fundamental technique will equip you with the confidence and capability to tackle a variety of projects with ease.

…

One of the key advantages of soldering copper wire is the reliability and durability of the connections it creates. Unlike other methods of joining wires, such as twisting or crimping, soldering forms a strong bond that is resistant to mechanical stress, vibration, and corrosion. This is especially important in applications where consistent electrical conductivity is essential, such as in electronic devices, automotive wiring, or home appliances. Moreover, soldering allows for a neat and compact connection that is less bulky and more aesthetically pleasing than other methods. This can be particularly advantageous in projects where space is limited, or where a professional finish is desired. In addition to its practical benefits, mastering the art of soldering copper wire can also be a rewarding and satisfying experience. There is a sense of accomplishment that comes from successfully creating a clean and secure connection, knowing that your handiwork will contribute to the functionality and longevity of your project. Whether you are soldering a simple circuit, repairing a broken wire, or crafting a custom jewelry piece, the precision and artistry involved in soldering can be a source of pride and fulfillment. As with any skill, practice makes perfect when it comes to soldering copper wire. Don’t be discouraged if your first few attempts are less than perfect – learning to solder takes time, patience, and persistence. Take the time to experiment with different techniques, hone your soldering skills, and gradually build your confidence and expertise. Remember to always prioritize safety when soldering copper wire. Ensure your workspace is well-ventilated to prevent inhaling harmful fumes, and use appropriate safety equipment such as safety glasses and heat-resistant gloves to protect yourself from burns and injuries. Keep your workspace organized and free of clutter to minimize the risk of accidents. In conclusion, mastering the art of soldering copper wire is a valuable skill that will serve you well in a wide range of projects and applications. Whether you are a DIY enthusiast, a hobbyist, or a professional, the ability to solder copper wire effectively opens up a world of possibilities and empowers you to create, repair, and innovate with confidence. By understanding the basics of soldering, selecting the right tools and materials, and mastering the techniques involved, you can solder copper wire like a pro and achieve strong, reliable connections that stand the test of time. So, roll up your sleeves, grab your soldering iron, and dive into the world of soldering – the possibilities are endless!

One of the key advantages of soldering copper wire is the reliability and durability of the connections it creates. Unlike other methods of joining wires, such as twisting or crimping, soldering forms a strong bond that is resistant to mechanical stress, vibration, and corrosion. This is especially important in applications where consistent electrical conductivity is essential, such as in electronic devices, automotive wiring, or home appliances. Moreover, soldering allows for a neat and compact connection that is less bulky and more aesthetically pleasing than other methods. This can be particularly advantageous in projects where space is limited, or where a professional finish is desired. In addition to its practical benefits, mastering the art of soldering copper wire can also be a rewarding and satisfying experience. There is a sense of accomplishment that comes from successfully creating a clean and secure connection, knowing that your handiwork will contribute to the functionality and longevity of your project. Whether you are soldering a simple circuit, repairing a broken wire, or crafting a custom jewelry piece, the precision and artistry involved in soldering can be a source of pride and fulfillment. As with any skill, practice makes perfect when it comes to soldering copper wire. Don’t be discouraged if your first few attempts are less than perfect – learning to solder takes time, patience, and persistence. Take the time to experiment with different techniques, hone your soldering skills, and gradually build your confidence and expertise. Remember to always prioritize safety when soldering copper wire. Ensure your workspace is well-ventilated to prevent inhaling harmful fumes, and use appropriate safety equipment such as safety glasses and heat-resistant gloves to protect yourself from burns and injuries. Keep your workspace organized and free of clutter to minimize the risk of accidents. In conclusion, mastering the art of soldering copper wire is a valuable skill that will serve you well in a wide range of projects and applications. Whether you are a DIY enthusiast, a hobbyist, or a professional, the ability to solder copper wire effectively opens up a world of possibilities and empowers you to create, repair, and innovate with confidence. By understanding the basics of soldering, selecting the right tools and materials, and mastering the techniques involved, you can solder copper wire like a pro and achieve strong, reliable connections that stand the test of time. So, roll up your sleeves, grab your soldering iron, and dive into the world of soldering – the possibilities are endless!

Your comment submitted.