When it comes to setting up electrical systems, whether it’s for residential, commercial, or industrial purposes, choosing the right type of cable is crucial. One of the key decisions to make is whether to use flexible or rigid cable. Both types have their own unique characteristics and applications, and understanding the differences between them can help you make an informed decision that best suits your needs. Flexible cable and rigid cable are two common types of electrical cables used in various applications. Each type has its own advantages and disadvantages, making them suitable for different scenarios. Let’s delve deeper into the world of flexible and rigid cables to understand their properties, applications, and benefits.

.

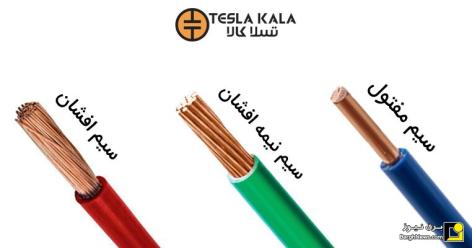

Flexible Cable: Flexible cables are designed to bend and flex easily, making them ideal for applications where the cable needs to move or bend frequently. These cables are made up of multiple strands of wire, which gives them the flexibility to bend without breaking. Flexible cables are usually more expensive than rigid cables due to their complex construction, but they offer greater versatility in terms of installation and use. One of the key advantages of flexible cables is their ability to withstand repeated bending and flexing without losing their electrical properties. This makes them ideal for applications where the cable needs to move or change position regularly, such as in robotics, machinery, and portable devices. Flexible cables can also be used in tight spaces where rigid cables may not fit or maneuver easily. Another benefit of flexible cables is their resistance to vibration and movement. In applications where there is constant vibration or movement, such as in automotive or aerospace industries, flexible cables provide a reliable and durable solution. Their ability to absorb mechanical stress and maintain their electrical conductivity makes them a preferred choice in such scenarios. Additionally, flexible cables are often easier to install and route compared to rigid cables. Their flexibility allows for easier handling and maneuvering around obstacles, making the installation process more efficient. This can result in cost savings and reduced installation time, especially in complex or tight spaces where flexibility is key. Rigid Cable: On the other hand, rigid cables are designed to maintain their shape and structure, making them suitable for applications where stability and durability are crucial. Rigid cables are made of solid copper or aluminum conductors, which are encased in a protective sheath to provide mechanical and environmental protection. While rigid cables are less flexible than their flexible counterparts, they offer several advantages in terms of strength and performance. One of the main benefits of rigid cables is their high mechanical strength and resistance to crushing and deformation. This makes them ideal for applications where the cable needs to support heavy loads or withstand external forces, such as in construction, mining, or infrastructure projects. Rigid cables can also be buried underground or installed in harsh environments without compromising their performance, making them a reliable choice for outdoor applications. Rigid cables are also known for their high electrical conductivity and low resistance, which ensures efficient transmission of electricity over long distances. This makes them suitable for high-power applications where low voltage drop and high efficiency are essential, such as in power distribution networks, industrial machinery, and renewable energy systems.

Flexible Cable: Flexible cables are designed to bend and flex easily, making them ideal for applications where the cable needs to move or bend frequently. These cables are made up of multiple strands of wire, which gives them the flexibility to bend without breaking. Flexible cables are usually more expensive than rigid cables due to their complex construction, but they offer greater versatility in terms of installation and use. One of the key advantages of flexible cables is their ability to withstand repeated bending and flexing without losing their electrical properties. This makes them ideal for applications where the cable needs to move or change position regularly, such as in robotics, machinery, and portable devices. Flexible cables can also be used in tight spaces where rigid cables may not fit or maneuver easily. Another benefit of flexible cables is their resistance to vibration and movement. In applications where there is constant vibration or movement, such as in automotive or aerospace industries, flexible cables provide a reliable and durable solution. Their ability to absorb mechanical stress and maintain their electrical conductivity makes them a preferred choice in such scenarios. Additionally, flexible cables are often easier to install and route compared to rigid cables. Their flexibility allows for easier handling and maneuvering around obstacles, making the installation process more efficient. This can result in cost savings and reduced installation time, especially in complex or tight spaces where flexibility is key. Rigid Cable: On the other hand, rigid cables are designed to maintain their shape and structure, making them suitable for applications where stability and durability are crucial. Rigid cables are made of solid copper or aluminum conductors, which are encased in a protective sheath to provide mechanical and environmental protection. While rigid cables are less flexible than their flexible counterparts, they offer several advantages in terms of strength and performance. One of the main benefits of rigid cables is their high mechanical strength and resistance to crushing and deformation. This makes them ideal for applications where the cable needs to support heavy loads or withstand external forces, such as in construction, mining, or infrastructure projects. Rigid cables can also be buried underground or installed in harsh environments without compromising their performance, making them a reliable choice for outdoor applications. Rigid cables are also known for their high electrical conductivity and low resistance, which ensures efficient transmission of electricity over long distances. This makes them suitable for high-power applications where low voltage drop and high efficiency are essential, such as in power distribution networks, industrial machinery, and renewable energy systems.

..

The solid conductors in rigid cables provide a stable and reliable electrical connection, ensuring consistent performance under varying conditions. Furthermore, rigid cables offer better protection against environmental factors such as moisture, heat, and chemicals. The protective sheath of rigid cables acts as a barrier against external elements, preventing damage and ensuring long-term reliability. This makes rigid cables a preferred choice for applications where the cable is exposed to harsh conditions or needs to withstand extreme temperatures. Flexible vs. Rigid Cable: When deciding between flexible and rigid cables, it’s important to consider the specific requirements of your application and weigh the advantages of each type. Flexible cables are best suited for applications that require frequent bending and flexing, such as in robotics, automation, and portable devices. Their flexibility and ease of installation make them a versatile choice for dynamic environments where movement is a key factor. On the other hand, rigid cables are preferred for applications that demand stability, durability, and high mechanical strength, such as in construction, infrastructure, and power distribution. Their solid construction and protective sheath provide reliable performance in challenging environments, ensuring the safety and efficiency of electrical systems. Rigid cables are the go-to option for long-term installations where reliability and performance are paramount. In conclusion, both flexible and rigid cables play a crucial role in modern electrical systems, offering a range of benefits and features to suit different applications. By understanding the properties and advantages of each type, you can choose the right cable for your specific needs and ensure the success of your electrical project. Whether you opt for flexible cables for their versatility and flexibility or rigid cables for their stability and reliability, investing in high-quality cables is essential for the efficiency and safety of your electrical systems.

The solid conductors in rigid cables provide a stable and reliable electrical connection, ensuring consistent performance under varying conditions. Furthermore, rigid cables offer better protection against environmental factors such as moisture, heat, and chemicals. The protective sheath of rigid cables acts as a barrier against external elements, preventing damage and ensuring long-term reliability. This makes rigid cables a preferred choice for applications where the cable is exposed to harsh conditions or needs to withstand extreme temperatures. Flexible vs. Rigid Cable: When deciding between flexible and rigid cables, it’s important to consider the specific requirements of your application and weigh the advantages of each type. Flexible cables are best suited for applications that require frequent bending and flexing, such as in robotics, automation, and portable devices. Their flexibility and ease of installation make them a versatile choice for dynamic environments where movement is a key factor. On the other hand, rigid cables are preferred for applications that demand stability, durability, and high mechanical strength, such as in construction, infrastructure, and power distribution. Their solid construction and protective sheath provide reliable performance in challenging environments, ensuring the safety and efficiency of electrical systems. Rigid cables are the go-to option for long-term installations where reliability and performance are paramount. In conclusion, both flexible and rigid cables play a crucial role in modern electrical systems, offering a range of benefits and features to suit different applications. By understanding the properties and advantages of each type, you can choose the right cable for your specific needs and ensure the success of your electrical project. Whether you opt for flexible cables for their versatility and flexibility or rigid cables for their stability and reliability, investing in high-quality cables is essential for the efficiency and safety of your electrical systems.

…

The choice between flexible and rigid cables ultimately depends on the unique requirements of your project. It’s important to consider factors such as the environment in which the cables will be installed, the amount of movement or bending required, the electrical load they will carry, and the level of protection needed against external elements. By carefully evaluating these factors, you can select the most suitable type of cable that will ensure optimal performance and longevity for your electrical system. In addition to the physical characteristics of flexible and rigid cables, it’s also essential to consider the regulatory standards and certifications that apply to these cables. Ensuring that the cables meet industry standards for safety, performance, and quality is crucial to avoiding potential hazards and ensuring compliance with regulations. Choosing cables that are certified by recognized authorities can provide peace of mind and assurance that your electrical system meets the necessary requirements. When purchasing cables, it’s important to source them from reputable suppliers or manufacturers who adhere to strict quality control measures and standards. High-quality cables not only provide better performance and reliability but also reduce the risk of malfunctions, downtime, and safety hazards. Investing in premium cables may involve a higher initial cost, but the long-term benefits in terms of durability, efficiency, and safety far outweigh the upfront investment. Furthermore, proper installation and maintenance of cables are essential to ensuring their longevity and performance. Following manufacturer’s guidelines for installation, securing, and routing of cables is crucial to prevent damage, overheating, or electrical faults. Regular inspections and maintenance of cables can help detect any issues early on and prevent potential failures that could lead to downtime or safety risks. In conclusion, the choice between flexible and rigid cables depends on the specific requirements of your electrical project, considering factors such as flexibility, durability, stability, and environmental conditions. Both types of cables offer unique advantages and are suitable for different applications, so it’s crucial to assess your needs carefully before making a decision. By selecting high-quality cables, following industry standards, and ensuring proper installation and maintenance, you can create a reliable and efficient electrical system that meets your operational requirements and regulatory compliance. Choose your cables wisely to ensure the success and safety of your electrical installations.

The choice between flexible and rigid cables ultimately depends on the unique requirements of your project. It’s important to consider factors such as the environment in which the cables will be installed, the amount of movement or bending required, the electrical load they will carry, and the level of protection needed against external elements. By carefully evaluating these factors, you can select the most suitable type of cable that will ensure optimal performance and longevity for your electrical system. In addition to the physical characteristics of flexible and rigid cables, it’s also essential to consider the regulatory standards and certifications that apply to these cables. Ensuring that the cables meet industry standards for safety, performance, and quality is crucial to avoiding potential hazards and ensuring compliance with regulations. Choosing cables that are certified by recognized authorities can provide peace of mind and assurance that your electrical system meets the necessary requirements. When purchasing cables, it’s important to source them from reputable suppliers or manufacturers who adhere to strict quality control measures and standards. High-quality cables not only provide better performance and reliability but also reduce the risk of malfunctions, downtime, and safety hazards. Investing in premium cables may involve a higher initial cost, but the long-term benefits in terms of durability, efficiency, and safety far outweigh the upfront investment. Furthermore, proper installation and maintenance of cables are essential to ensuring their longevity and performance. Following manufacturer’s guidelines for installation, securing, and routing of cables is crucial to prevent damage, overheating, or electrical faults. Regular inspections and maintenance of cables can help detect any issues early on and prevent potential failures that could lead to downtime or safety risks. In conclusion, the choice between flexible and rigid cables depends on the specific requirements of your electrical project, considering factors such as flexibility, durability, stability, and environmental conditions. Both types of cables offer unique advantages and are suitable for different applications, so it’s crucial to assess your needs carefully before making a decision. By selecting high-quality cables, following industry standards, and ensuring proper installation and maintenance, you can create a reliable and efficient electrical system that meets your operational requirements and regulatory compliance. Choose your cables wisely to ensure the success and safety of your electrical installations.

Your comment submitted.