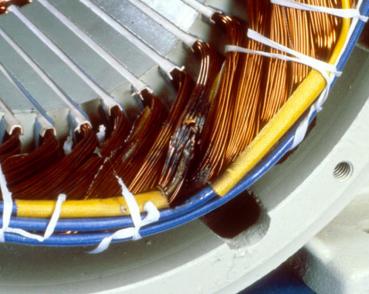

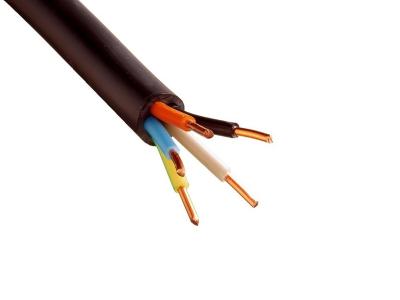

If you’re in the market for electrical cables, you may have come across the choice between armoured cables and rubber cables. Both of these types of cables serve specific purposes and have unique characteristics that make them suitable for different applications. In this article, we will explore the differences between armoured cables and rubber cables to help you make an informed decision when selecting the right cable for your needs. Armoured cables are designed for heavy-duty applications where extra protection is required. These cables are constructed with a layer of steel or aluminum wires that provide mechanical protection and shield the inner components from external factors such as moisture, chemicals, and physical damage. Armoured cables are commonly used in industrial settings, construction sites, and outdoor installations where the cable is exposed to harsh conditions. On the other hand, rubber cables are flexible and resilient cables that are often used in situations where the cable needs to bend and flex without breaking. Rubber cables are made from high-quality rubber compounds that are resistant to oil, abrasion, and extreme temperatures. These cables are commonly used in portable equipment, machinery, and power tools where flexibility and durability are essential. One of the key differences between armoured cables and rubber cables is their construction. Armoured cables have an additional layer of protection in the form of steel or aluminum wires, while rubber cables are composed of a single conductive core surrounded by a layer of flexible rubber insulation. This difference in construction makes armoured cables more suitable for rugged environments, while rubber cables are better suited for applications that require flexibility. In terms of performance, armoured cables offer superior protection against physical damage and external elements compared to rubber cables.

.

The steel or aluminum wires in armoured cables provide excellent mechanical strength and durability, making them ideal for installations where the cable may be exposed to hazards such as crushing, impact, or abrasion. Additionally, the armouring in these cables helps to prevent moisture ingress and corrosion, ensuring the long-term reliability of the electrical connection. Rubber cables, on the other hand, excel in applications that require flexibility and resistance to harsh environments. The flexible rubber insulation of these cables allows them to bend and twist without cracking or breaking, making them ideal for use in situations where frequent movement or vibration is present. Rubber cables are also well-suited for outdoor installations where they may be exposed to sunlight, oil, or chemicals, as the rubber compounds used in their construction offer excellent resistance to these factors. When it comes to installation, armoured cables and rubber cables have different requirements. Armoured cables are typically more challenging to install due to their heavier and bulkier construction. These cables may require special tools and equipment to cut and terminate the armouring properly, adding to the overall installation time and cost. On the other hand, rubber cables are lightweight and easy to handle, making them quick and simple to install in most applications. In terms of cost, armoured cables are generally more expensive than rubber cables due to the additional materials and manufacturing processes involved in their production.

The steel or aluminum wires in armoured cables provide excellent mechanical strength and durability, making them ideal for installations where the cable may be exposed to hazards such as crushing, impact, or abrasion. Additionally, the armouring in these cables helps to prevent moisture ingress and corrosion, ensuring the long-term reliability of the electrical connection. Rubber cables, on the other hand, excel in applications that require flexibility and resistance to harsh environments. The flexible rubber insulation of these cables allows them to bend and twist without cracking or breaking, making them ideal for use in situations where frequent movement or vibration is present. Rubber cables are also well-suited for outdoor installations where they may be exposed to sunlight, oil, or chemicals, as the rubber compounds used in their construction offer excellent resistance to these factors. When it comes to installation, armoured cables and rubber cables have different requirements. Armoured cables are typically more challenging to install due to their heavier and bulkier construction. These cables may require special tools and equipment to cut and terminate the armouring properly, adding to the overall installation time and cost. On the other hand, rubber cables are lightweight and easy to handle, making them quick and simple to install in most applications. In terms of cost, armoured cables are generally more expensive than rubber cables due to the additional materials and manufacturing processes involved in their production.

..

The steel or aluminum armouring in armoured cables adds to the overall cost of the cable, making them a higher-priced option compared to rubber cables. However, the superior protection and durability provided by armoured cables may justify the higher initial investment in situations where the cable is exposed to challenging conditions. In conclusion, the choice between armoured cables and rubber cables ultimately depends on the specific requirements of your application. If you need a cable that offers superior mechanical protection and resistance to external factors, an armoured cable may be the best choice for you. On the other hand, if flexibility, durability, and cost-effectiveness are your primary concerns, a rubber cable may be more suitable for your needs. Before making a decision, carefully consider the environment in which the cable will be used, the type of equipment it will be connected to, and your budget constraints. By selecting the right cable for your application, you can ensure a reliable and efficient electrical connection that meets your needs for years to come. When it comes to long-term performance and durability, armoured cables have a clear advantage over rubber cables in challenging environments. The additional layer of steel or aluminum armouring provides unmatched protection against physical damage, moisture, and corrosion, making armoured cables a reliable choice for critical applications where the cable is subjected to harsh conditions. Furthermore, armoured cables are designed to withstand a wide range of temperatures, making them suitable for both indoor and outdoor installations. Whether you need to run cables through a hot industrial factory or bury them underground in cold winter conditions, armoured cables can provide the stability and reliability needed to maintain a consistent electrical connection. On the other hand, rubber cables are best suited for applications that require flexibility and ease of installation. The pliable rubber insulation of these cables allows them to bend and flex without compromising their integrity, making them a popular choice for portable equipment, power tools, and temporary installations where frequent movement is required. While rubber cables may not offer the same level of physical protection as armoured cables, they excel in situations where flexibility and ease of handling are top priorities.

The steel or aluminum armouring in armoured cables adds to the overall cost of the cable, making them a higher-priced option compared to rubber cables. However, the superior protection and durability provided by armoured cables may justify the higher initial investment in situations where the cable is exposed to challenging conditions. In conclusion, the choice between armoured cables and rubber cables ultimately depends on the specific requirements of your application. If you need a cable that offers superior mechanical protection and resistance to external factors, an armoured cable may be the best choice for you. On the other hand, if flexibility, durability, and cost-effectiveness are your primary concerns, a rubber cable may be more suitable for your needs. Before making a decision, carefully consider the environment in which the cable will be used, the type of equipment it will be connected to, and your budget constraints. By selecting the right cable for your application, you can ensure a reliable and efficient electrical connection that meets your needs for years to come. When it comes to long-term performance and durability, armoured cables have a clear advantage over rubber cables in challenging environments. The additional layer of steel or aluminum armouring provides unmatched protection against physical damage, moisture, and corrosion, making armoured cables a reliable choice for critical applications where the cable is subjected to harsh conditions. Furthermore, armoured cables are designed to withstand a wide range of temperatures, making them suitable for both indoor and outdoor installations. Whether you need to run cables through a hot industrial factory or bury them underground in cold winter conditions, armoured cables can provide the stability and reliability needed to maintain a consistent electrical connection. On the other hand, rubber cables are best suited for applications that require flexibility and ease of installation. The pliable rubber insulation of these cables allows them to bend and flex without compromising their integrity, making them a popular choice for portable equipment, power tools, and temporary installations where frequent movement is required. While rubber cables may not offer the same level of physical protection as armoured cables, they excel in situations where flexibility and ease of handling are top priorities.

…

The resilient nature of rubber cables makes them ideal for use in dynamic environments where the cable needs to move and adapt to changing conditions without wear or tear. In terms of maintenance, armoured cables typically require less upkeep compared to rubber cables. The rugged construction of armoured cables minimizes the risk of damage and ensures long-term performance with minimal intervention. In contrast, rubber cables may require more frequent inspections and replacements due to their susceptibility to wear and tear over time, especially in high-stress environments. It’s essential to factor in the overall lifecycle cost when choosing between armoured cables and rubber cables. While armoured cables may have a higher upfront cost, their long-lasting durability and reliability can result in cost savings over the cable’s lifespan. On the other hand, the lower initial cost of rubber cables may be offset by the need for more frequent replacements and maintenance, leading to higher long-term expenses. In conclusion, both armoured cables and rubber cables have their unique strengths and weaknesses, making each type suitable for specific applications. Armoured cables are ideal for heavy-duty installations that require superior protection and durability, while rubber cables excel in situations that necessitate flexibility and ease of handling. Before making a decision, carefully evaluate your project requirements, environmental conditions, and budget constraints to determine the most suitable cable type for your needs. By selecting the right cable for your application, you can ensure a reliable electrical connection that meets your performance expectations and withstands the test of time. Whether you opt for the robust protection of armoured cables or the flexibility of rubber cables, investing in high-quality cables from a reputable manufacturer is key to ensuring safety, reliability, and efficiency in your electrical installations. Make an informed decision based on your specific needs and requirements to find the perfect cable solution that will serve you well for years to come.

The resilient nature of rubber cables makes them ideal for use in dynamic environments where the cable needs to move and adapt to changing conditions without wear or tear. In terms of maintenance, armoured cables typically require less upkeep compared to rubber cables. The rugged construction of armoured cables minimizes the risk of damage and ensures long-term performance with minimal intervention. In contrast, rubber cables may require more frequent inspections and replacements due to their susceptibility to wear and tear over time, especially in high-stress environments. It’s essential to factor in the overall lifecycle cost when choosing between armoured cables and rubber cables. While armoured cables may have a higher upfront cost, their long-lasting durability and reliability can result in cost savings over the cable’s lifespan. On the other hand, the lower initial cost of rubber cables may be offset by the need for more frequent replacements and maintenance, leading to higher long-term expenses. In conclusion, both armoured cables and rubber cables have their unique strengths and weaknesses, making each type suitable for specific applications. Armoured cables are ideal for heavy-duty installations that require superior protection and durability, while rubber cables excel in situations that necessitate flexibility and ease of handling. Before making a decision, carefully evaluate your project requirements, environmental conditions, and budget constraints to determine the most suitable cable type for your needs. By selecting the right cable for your application, you can ensure a reliable electrical connection that meets your performance expectations and withstands the test of time. Whether you opt for the robust protection of armoured cables or the flexibility of rubber cables, investing in high-quality cables from a reputable manufacturer is key to ensuring safety, reliability, and efficiency in your electrical installations. Make an informed decision based on your specific needs and requirements to find the perfect cable solution that will serve you well for years to come.

Your comment submitted.