Wires and cables are of different sizes that change the characteristics of each one by changing the insulation and size. 11kv cable with XLPE or PVC is a widely used medium voltage cable.

Heating, ventilation and air conditioning (HVAC) cables are often used as an alternative transmission technology when overhead lines cannot be used for various reasons, such as in densely populated and protected areas, over rivers or offshore.

Insulation for extruded cables is provided using cross-linked polyethylene (XLPE). Due to the progress in material science, XLPE has achieved high dielectric strength, low dielectric constant, high insulation resistance and strong mechanical qualities. These properties combine to make it an effective insulating medium for transmitting power underground.

XLPE cables used in HVAC systems can be divided into two distinct types:

Cables located in the ground

Submarine cables

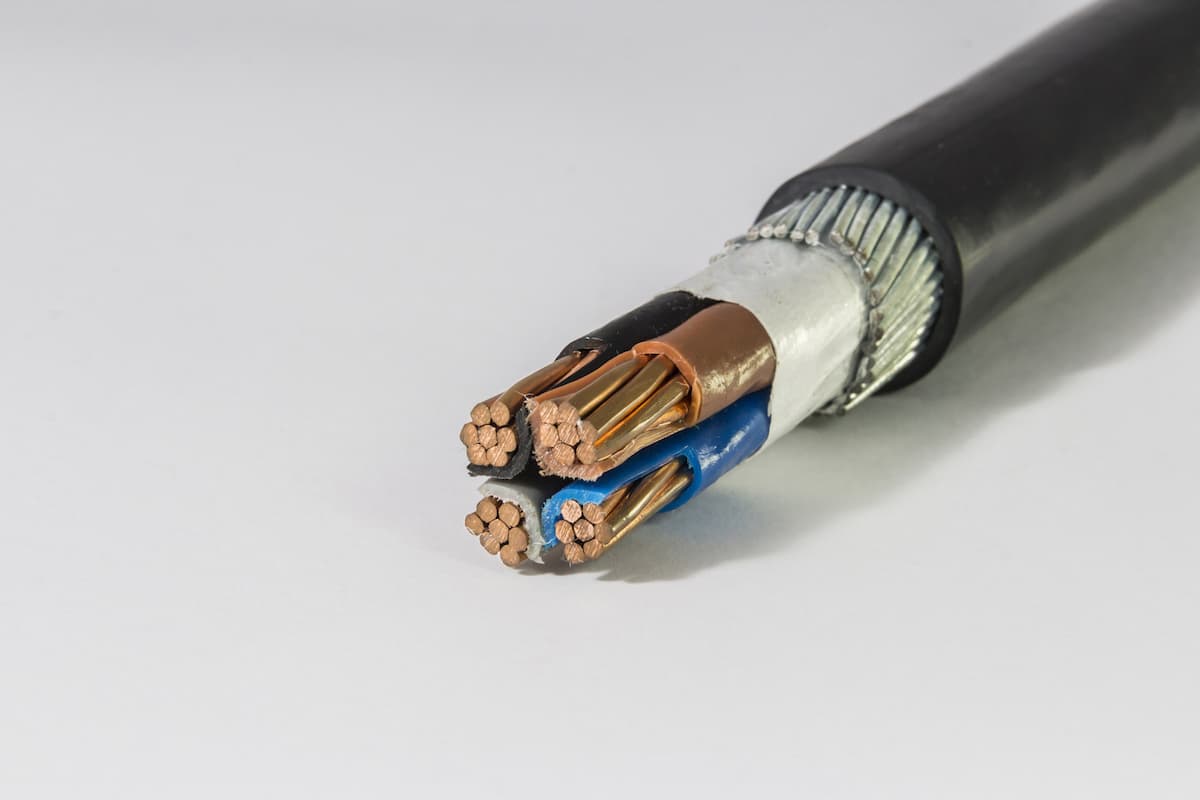

The number of cores (conductors) that are woven together to make a cable is another way to distinguish each type from another. One core or three cores may be configured in its architecture.

On a global scale, HVAC cables are widely used at voltage levels up to a maximum voltage of 550 kV. This is the maximum cable rating. Since 1995 insulated XLPE extruded cables have been used at 275 kV and since around 2000 at 400 kV.

Extruded insulated cables designed for use with HVAC systems are also often used for subsea connections. Currently, HVAC system cables that have extruded insulation can cover transmission system voltages up to 550 kV.

Components and enablers

Cable located in the ground:

Materials used for insulation (XLPE)

A barrier against water

The outer shell is not made of metal

Submarine cable:

One layer of insulation (XLPE)

core and sheath (semiconductor)

Protective armor (galvanized steel wires)

External cedar (bitumen and polypropylene thread)

Benefits as well as areas of application

XLPE’s low dielectric loss makes it an ideal insulation for medium and high voltage cables. This is the main advantage of using XLPE. The dielectric loss factor is about one-tenth that of paper-insulated cables and about a hundred times lower than that of PVC-insulated cables.

In addition, advances in manufacturing and installation processes have contributed to a significant increase in the use of this type, leading to a dramatic increase in its overall prevalence.

At least forty years can be expected from XLPE cables during their lifetime. The highest temperature that HVAC XLPE can withstand in a short circuit is about 250°C, and it can also withstand a temperature of 90°C. There are a few issues to overcome when using HVAC systems that use XLPE cables.

These challenges include long outage times after damage or failure, transient behavior, and reactive power provided by cables. Conducting in-depth risk assessments on a case-by-case basis is essential for network operation.

Technology readiness level

TRL 9 for HVAC cables used offshore having a voltage of 245 kV or less, as well as onshore HVAC cables of the same rating

Technical Requirements Level 7 (TRL 7) for Terrestrial HVAC Cables with a Voltage Rating of 420 kV or Greater

Conduct research and development

Research is currently underway in the following areas: System integration margins due to reactive power compensation. partial discharge detection; fault localization; new environmentally friendly methods of lying; substrate material; 4000 square mm conductor; and long-term thermal stability of insulating materials.

Due to the strong mechanical protection provided by their aluminum wire armor (AWA) for single-core cables and their steel wire armor (SWA) for multi-core cables, these 11 kV cables are suitable for direct burial in the ground. .

These main armored MV power cables are often supplied with copper conductors. But upon request, they can also be delivered with aluminum conductors that comply with the standard of copper conductors.

Conductors made of copper are stranded, which classifies them as belonging to Class 2, while conductors made of aluminum comply with this requirement using solid, stranded structures (Class 1). .

Eland Cables supplied UK distribution network operators UKPN, SSE, Western Power Distribution (WPD), Northern Power Grid (NPG), Scottish Energy Network (SPEN) and Electricity Northwest with a range of DNO approved cables, including 6.35 voltages. /11 kV (ENW).

These cables are manufactured by a G81 approved supplier and adhere to the construction criteria of each DNO. Includes 11kV triplex cable that will be used for UKPN.

We offer a wide range of wires and cables with our product pricing policy in line with global market prices. You can easily contact us and be sure that you will get a relatively lower price than the market. So fill out the application form, let us know what you need and we’ll get back to you right away.

Your comment submitted.