Welding wire is used to connect two materials and strengthen it, which can be used by connecting two metals together. Welding wire with different types of copper, silver, aluminum and steel can be seen in the market with different prices and it is used in welding based on efficiency. Welding wires are classified according to their characteristics in the welding industry, which include powder, solid, mig-mag, tick, etc. Basically, for metal sheets, they use its solid type, which can create a very smooth weld with shielding gas.

This kind of welding wire produces low odor and prevents respiratory diseases and asthma, but its topological variants contain oxidizing which can result in huge weight under any condition and are most commonly used for large parts. However, during the use of the welding wire, a series of points must be taken into consideration to bring high quality during the use of the welding. During the process of joints use it should be carried out in depth and special accuracy so that no defects should be observed during welding. Welding with weld wire is done by an expert and skilled person so as not to cause any damages which may occur in the weld person and also to avoid damage to the workpiece.

Silver copper welding wire

Welding wire has many applications in many different industries and can connect two metals easily. Copper and silver welding wire has countless fans and can be considered as a widely used tool in factories.

Be sure to keep in mind when using the welding wire and welding of the safety shoes of the helmet and the specific eyeglasses to avoid damage to the eye, since it may have irreparable risks during the use of the welding. It is also better to use welding sprays to prevent burns and electrocution risks during work. The welded wire must be carried out with high sensitivity and precision, and according to the metal type it is selected. As you know, copper alloys are interlinked with copper welding wire and calculated based on welding filler. The Amerzweh uses welding wire to fill the edges of the parts, which are used based on the part’s material. Copper wire welds have low boiling temperature and because of copper alloy it has high strength and durability and can show good strength at any atmospheric conditions. Also, silver welded wire can be used for brass joints such as valves etc. and because of fluctuations of copper and silver price are calculated daily. For the day price you can refer to the valid sites of these products to be informed of the original price and day of the products.

Aluminum copper welding wire

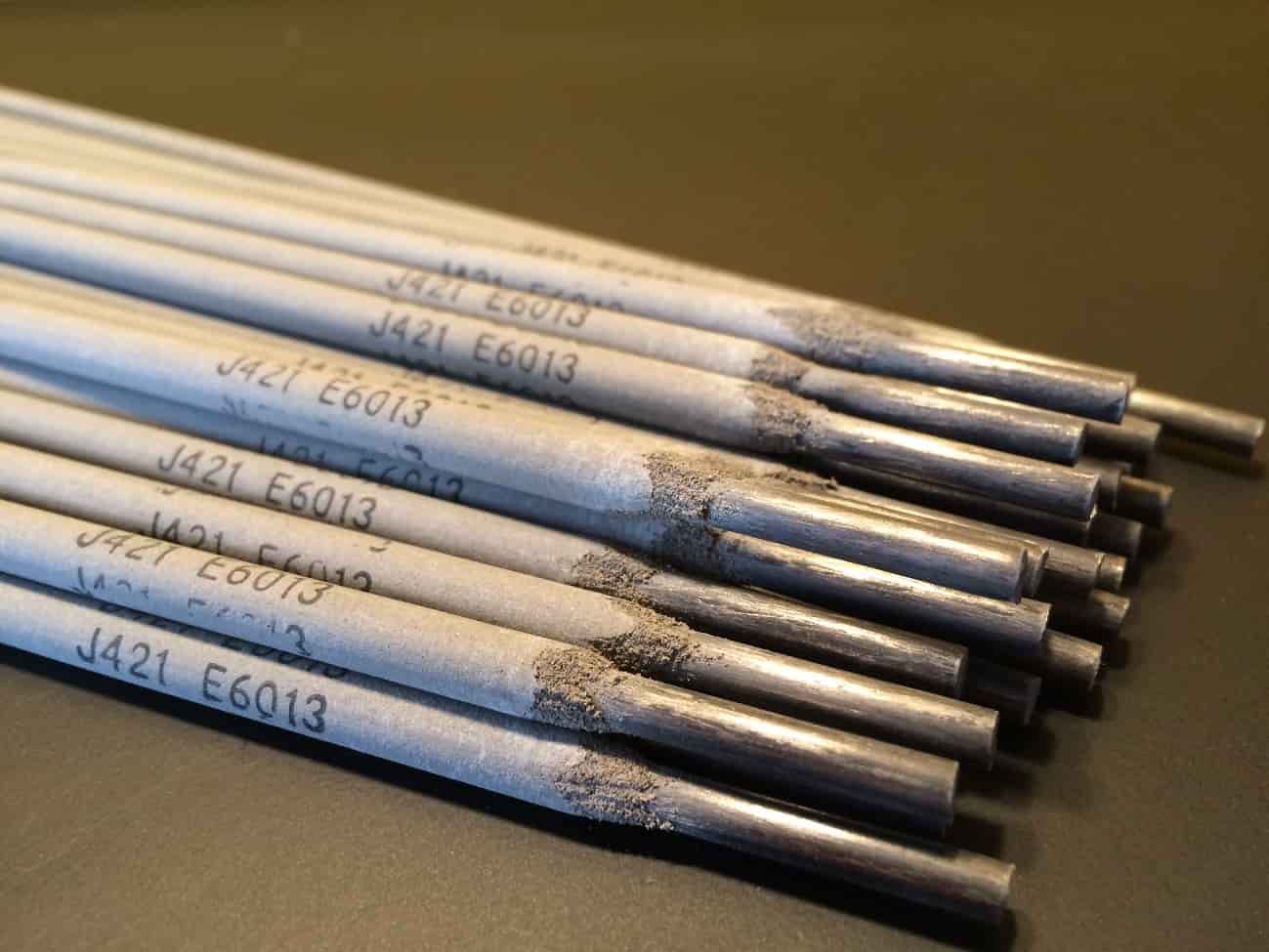

Copper welds are the most widely used and have been well received by many due to their non-toxic production. Copper and aluminum welds are evaluated based on three factors which affect the type of pressure and vibration. These welds are used for iron-to-copper joints which should be used at 25 percent of copper during use. Currently, welding powders have been observed in the market that if these powders were not properly combed, the fittings would not be well done. These powders are visible in retail markets with different volume packages at a variety of prices. Maybe you’re interested in how to use the welding wire vertical so that when it comes to a clean surface, it should be smooth.Also, the force of gravity causes molten materials to be pulled down due to heat and the strength of resistance to stick to a high limit. These welding wires with electrodes increase the deposits in the part by the welding machine and can play a significant role in speeding up the connection. However, the more resistant the material, the more difficult the welding wire will be during use, and it is better that its surface is very clean and smooth so that the welding operation is successful.

Copper steel welding wire

The welds are most commonly used when the metal fuses together through the heat. Copper-Steel welded wire is used for various industries such as construction and automation, and can be seen in the market with a variety of volume and price. Today, many producers have created different types of welding wire and wire, which have different price ranges and thickness. However, it is best to visit reputable sites and sites when you are shopping to ensure its quality and quality.Copper welded wire is made into wire and belt forms, which are used as oxygen kit by welding machine tubes with flame adjustment. Welders do this with special accuracy and with due to the perfect security and the use of necessary equipment such as clothing, cover, gloves and hats for fitting the two pieces are done properly. Some of the wire-seeps have cadmium that produces dangerous toxins and is harmful to human health. These wires are advanced with the technology and devices that are non-cadmium-free and can exhibit high strength and strength. This type of welded wire does not change the structure with any environmental or atmospheric conditions and can be used for many years.

This collection is one of the reliable centers that has been providing all kinds of welding wire with the best quality and reasonable price for several years. On this site, you can place an order for all kinds of welding wire without the presence of intermediaries and get it delivered to your home in the shortest possible time. This collection has launched the desired site so that for the convenience of customers and to save time and save time, they can easily order and finalize their purchase with the best choice.

Your comment submitted.