One of the most important tools for connecting and welding Addon is the iron welding wire, which is found in various types like co2, TIG, Metal core etc. and usually with PVC polyethylene in the market and you can do the joggers that are uniform. Use this with argon gas, and it is better to know that this product is in the form of a rod in the form of an object with copper at one end and the other is covered with different kinds of non-metal lugs that we will discuss the advantages of this product. If you want to connect a series of thin metal to each other, it is better to use the welding wire because it can do this in a deep way and it does not create any limits on the thickness of the metal you want to weld, it is necessary to note that the metals connected with the welded wire are more flexible and resistant.

You can also use the welding wire to not produce many products because there is a series of dioxides in the different types of this product and on their cladding, which makes the production of this waste material significantly reduced. It’s better to just do welding to avoid any kind of dangerous action and use the welds that are specialized enough to handle these gear, and if you find the speed with which welding is important you can use the welds to make the process go faster. As the last advantage of the welding wire, it can be applied to the copper layer drawn over it and a quality protective coating for this product.

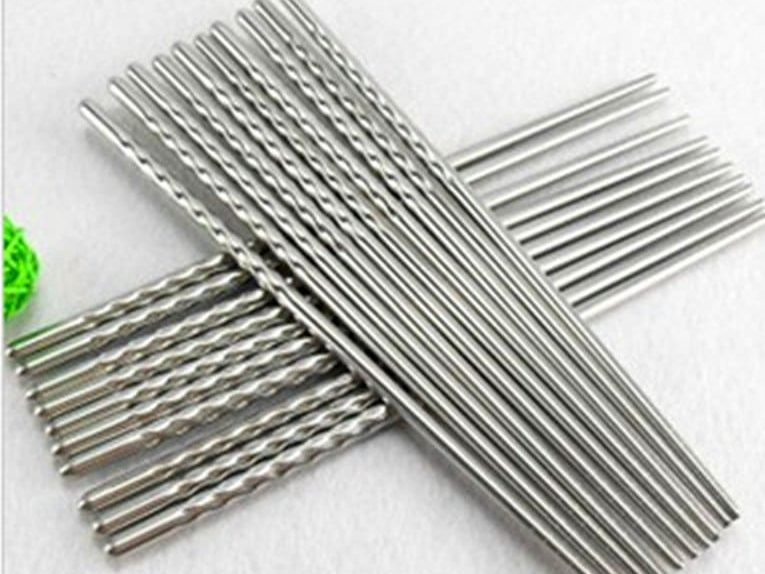

Co2 cast iron welding wire

The most important thing to consider when performing Brotherhood welds with co2 Cast iron welding is to make sure to use safety tools such as glasses and work gloves. In some cases, it is better to wear a manual mask in addition to glasses so as not to suffer physical damage as a result of welding or radiation that is produced. It is also better to use insulated panels instead of metals to prevent electrocution with carelessness, and it is necessary to know that these can not be enough to do so alone. You need to have enough expertise to know how to do welding, and to have the necessary training so that you can do without causing any welding problems. It is important to know that the application of the material we have mentioned is very important in the use of any kind of welded wire, which is one of the important raw materials for welding, and can perform the welding process of two metals with the best quality and durability, and to a large extent prevent the possible risks and damages caused by this work. It is also better to know that in addition to the different-coated welded wires, there are many types of non-cladding that are available in the market that are used in different industries.

Polyethylene cast iron welding wire

One of the things to notice is to pay attention to the type of metal on which you want to do with a welding mask and you should choose on the basis of its material one of the kind of welding wire such as polyethylene cast iron or non-ferrous etc, i.e. if you want to connect copper metals together you can’t use iron welding wire because the penetration rate of these metals is different and if you use the wrong items, your useful welding life will greatly decrease and the durability and low strength. The welded wire is usually coated with various materials, including alkaline coating, retili, rutilly with iron powder, cellulose and acidic coating, each of which is different in thickness and permeability, and therefore have different uses and applications, but the use of each of them can eventually make the welding place on the metal well enough and prevent the corruption of the part, create electrical arc with better stability and quality, as well as the scraps of the metal that separate from the metal during welding, according to the neutral material that prevents the welding and the welding process of these individuals.

PVC cast iron welding wire

It is best to know that different types of automatic welding with welding wire, such as PVC welded wire, are used in industries such as automobile and transport, manufacturing fixed equipment such as pressure vessel and others, and due to the different penetration rate they can have based on their material, it is possible to even connect two very thin metal and perform this with the lowest error and highest quality level. Considering that we are living in a modern world and there are all kinds of machines that have been able to facilitate our daily tasks, you should also know that with the use of wire jocks, we can create more accuracy and higher quality in the implementation of technology on machines and robots and finally make things easier and faster and you can provide this product in bulk or in part, you can take into account the quality of the welded wire, the productivity and cost you want to consider in order to meet your need to our home page and to visit our experienced customers in order to get the best customer satisfaction of our product Provide the desired product.

Your comment submitted.