Various industrial wire and cable companies usually present their latest types of electrical innovation in PPT format, which shows the latest features.

When it comes to industry, nothing remains untouched in the process of evolution. The same applies to the technology used to make the wires. Ever since electricity paved the way for our spaces, we have been using wires and cables for our electrical needs. People often use terms like wire and cable interchangeably. However, they are completely different from each other.

The first way to separate them is to consider the wire as part of the cable. Wires are used as much or more often than cables. Simply put, a wire is usually a single wire or group of conductive materials such as copper or aluminum. While a cable consists of two or more insulated wires wrapped in a sheath.

The easiest way to tell the two apart is that wires are usually visible, but cables are usually insulated. Let’s learn more about the difference between wire and cable.

Electric cable

As mentioned earlier, a wire is a strand of conductors or a group of strands of conductors wrapped in an insulating sheath to prevent unwanted contact between the conductors.

Wire is generally used to carry electricity and telecommunication signals, but it can also be used for mechanical loads. There are basically two types of yarn, solid and filament.

While solid wire is actually a long, single conductor, stranded wire is made up of several strands of fine wire twisted together. Solid wire has low resistance and is ideal for use at higher frequencies.

Litz wire is more flexible and therefore has a longer life. For the same current carrying capacity, stranded wire also has a better cross-sectional area than solid wire.

Cable

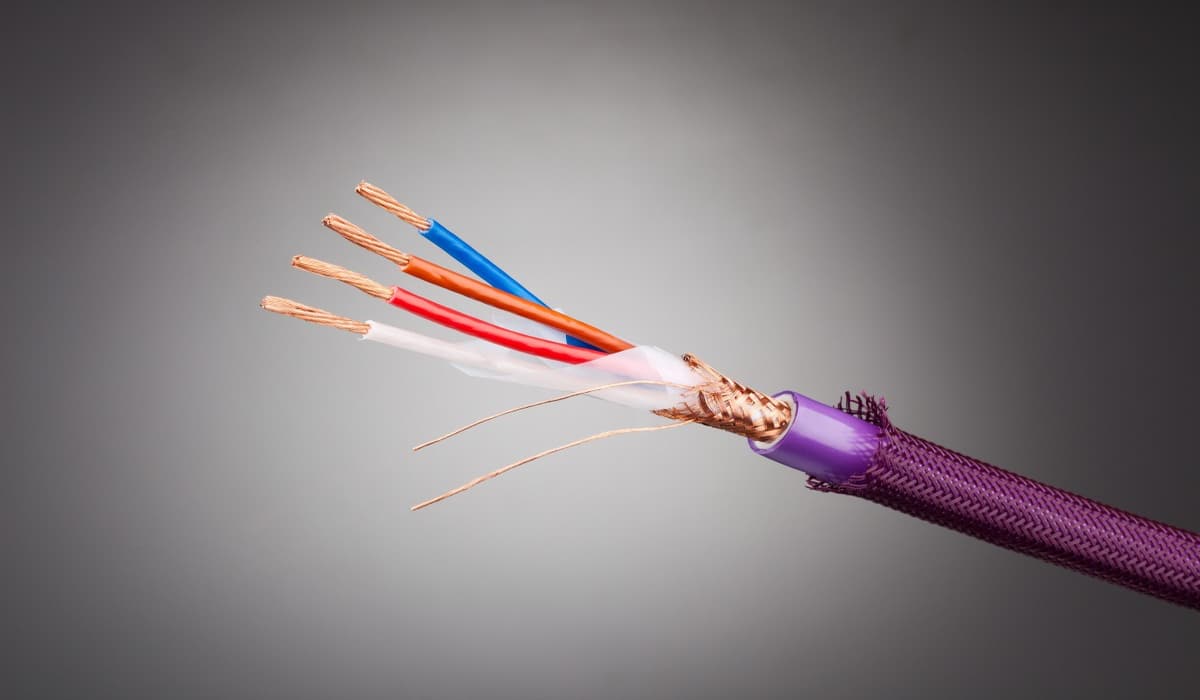

A cable is usually two or more wires that run together or are spliced, twisted, or braided together. They are mainly insulated for better protection of the wires.

Cables are mainly used for power transmission and transmission of electrical and telecommunication signals. There are different types of cables, such as twisted pair cables, coaxial cables, multiconductor cables, and fiber optic cables.

If we talk about twisted pair cable, it consists of two cables twisted around each other and is mainly used for signal transmission.

On the other hand, multicore cables consist of many conductors that are insulated from each other and are used to protect signal integrity by reducing hum, noise, and interference.

Coaxial cables are made of solid inner conductors surrounded by parallel outer foil conductors and protected by a layer of insulation and are commonly used in television cables. Fiber optic cables help transmit signals through a bundle of glass fibers.

Different types of electrical wire

Almost all electrical appliances require different types of cables and wires with different specifications.

Electrical codes officially refer to wires as “conductors,” but for convenience, we’ll call them wires. Wires can be bare wires, such as grounding and connecting electrical equipment and circuits. Or they may be coated with a material that only protects against corrosion and does not qualify as an official electrical insulator.

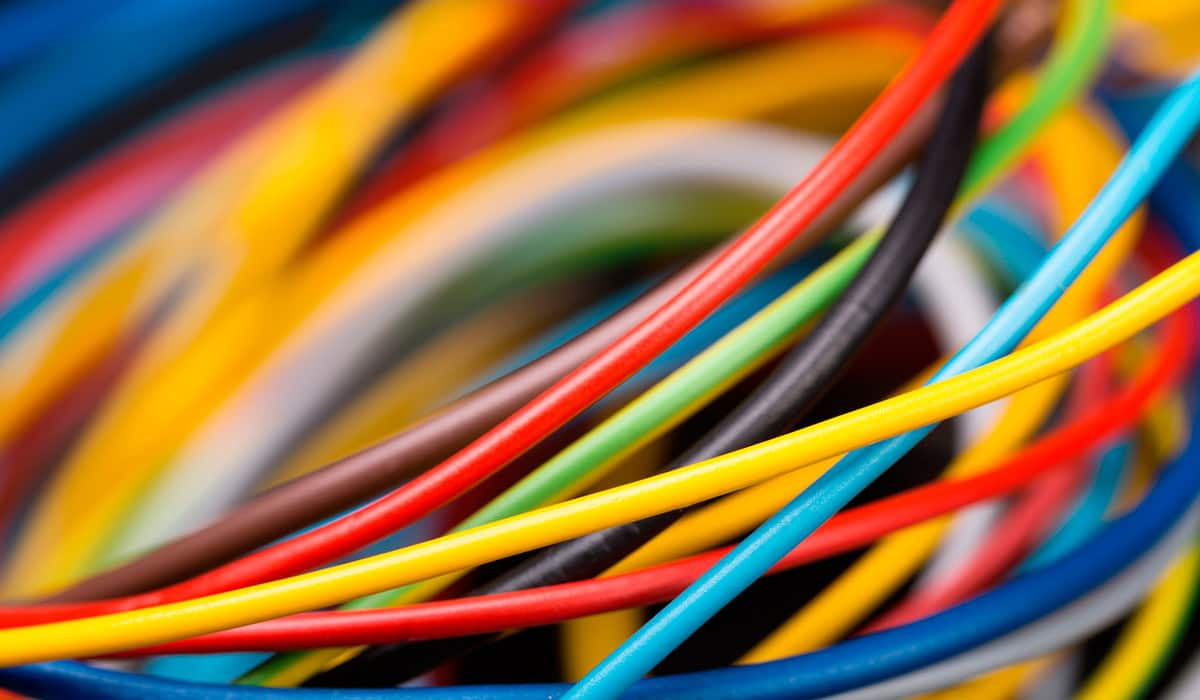

Most of you are probably familiar with colored wires covered in plastic insulation that are identified by a code. In the early days of wire, wires were insulated with black rubber.

Today, they insulate with various high-tech materials that can withstand harsh environments and conditions. These may be underground, submerged in water or exposed to sunlight, vibration, chemicals or heat.

Individual wires often have to be installed in metal or plastic pipes. The combination of wire and wire forms a complete wiring system.

A cable, on the other hand, is an assembly of two or more bare, covered or factory-insulated wires enclosed in an integral non-metallic or metallic sheath for physical protection. Unlike individual wires, cables are independent wiring systems and usually do not need to be installed in pipes.

We all feel guilty when we download new apps to our smartphones that are left out in user agreements. But in reality, the information on the wire or cable is an important user contract.

It is important to use the wire or cable in accordance with the electrical code and the manufacturer’s instructions. Knowing this information can mean the difference between a safe or unsafe electrical installation.

You can also get compliments from your local electrical inspector for doing your homework and paying attention to detail. A lot of important information is engraved on a wire. Here are some examples to see:

Look for UL, ETL, CSA, or other markings that indicate the cord has been evaluated to meet national safety standards.

Size, in American wire gauge (the national standard for determining wire size), such as “AWG 12” or in millimeters. Type of metal used for wire: CU for copper, AL for aluminum.

Look for the type of insulation, usually multiple levels, such as:

Type MTW (thread for machine tools);

Type THWN (thermoplastic/heat resistant, approved for wet environments, with nylon jacket);

Type THHN (thermoplastic/heat resistant, approved for dry or wet locations only, with nylon jacket).

For cables, the outer sheath contains similar information: the manufacturer’s name, UL or other safety certification marks, voltage rating, wire size inside the cable, cable type, and even the date of manufacture.

Wire insulation color and size

To ensure safety and uniformity, electrical codes require specific wires to be a specific color. Green is strictly reserved ground and connecting wires. The equipment ground wire ensures that fuses and circuit breakers open and interrupts current flow in the event of a ground fault.

Patch cords connect electrical systems to other metal systems in your home, such as plumbing, gas lines, cable TV, and telephones. This ensures that there will be no voltage difference between any of these systems in the event of an unusual power surge or nearby lightning strike. The voltage difference between the two systems can create a shock hazard.

White is meant to be neutral. Hotwires can be different colors, but manufacturers have developed common color schemes to maintain uniformity in the industry.

The colors of wires you are most likely to find in your home are:

Black or Red = Hot: Hot wires carry electrical current from electrical panels to switches, outlets, lamps, appliances, or other equipment.

WHITE = NEUTRAL: The neutral wire returns current to the panel and completes the circuit.

Stripe or Green = GROUND: In the event of a ground fault, the ground wire provides a low resistance and efficient path for the fault current to return to the board.

This will trip the circuit breaker or blow the fuse and interrupt the current to prevent electric shock or fire hazard. A ground fault occurs when a hot wire accidentally touches a grounded object.

If you remove the panel on the wall switch and the screwdriver slips and makes contact between the hot screw terminals and the metal breaker box, that is a ground fault. Therefore, it is important to always turn off the power and use a tester to make sure it is off before working on the circuit.

Different types of electrical cable

When it comes to the power industry and power transmission, many different types of questions may pop up in your mind, such as: How do power lines work?

A cable consists of a group of wires tightly wrapped around an outer sheath. Copper or aluminum insulated wires can be twisted or spliced together to form a reliable conductor.

Typically, cables consist of wire, insulation, and an outer sheath that protects the entire device. Since the main function of a cable is to transmit electrical energy from one place to another, insulation is very important to the safety of the cable as current flows through it.

Due to their electrical resistance, PVC, rubber or plastic materials are often used as insulation. Polyethylene or thermoplastic materials are usually used for the outer sheath. These materials are of high quality due to their flexibility and excellent performance in various applications.

Voltage ratings for cables are also based on wire type and insulation thickness. Compared to cables used in low voltage applications, high voltage cables often have stronger insulation.

Cables and their various functions

Cable is used in almost every environment including residential, commercial and industrial environments. Wiring is often used where electricity is needed.

The best cable depends on the intended application and the required voltage among the different types available. Basically, the three main categories of cables are computer, electrical and electrical. Wires may be specified in any of these categories as follows:

Coaxial – This type of cable is commonly used to send data signals, including satellite or antenna signals, to a television. They can be used in computer applications as well as for video transmission because they have a high level of isolation.

Information is transmitted through fiber optic cables, which are made of plastic or glass tubes, using light pulses. The applications of this type of cable can be mentioned in network, telecommunication and internet because it provides more speed and more reliability.

Flat cables – These types of electrical cables are suitable for more compact applications because they are lighter and more flexible with respect to space utilization. They are also known as ribbon cables and are often used in indoor computer systems due to their compatibility in tight spaces.

Composite or AV cables are used to get the best performance from video or audio devices, including HDMI, Ethernet, network and data transmission cables.

Composite cables are often required for home automation systems. Depending on the required application, special types such as coaxial and optical fiber are also offered in this category.

Industrial settings often have high voltage applications that require the inclusion of power electronics cables. Environments such as offices with many large machines and buildings with installed control systems are typical.

Composite or AV cables are used to get the best performance from video or audio devices, including HDMI, Ethernet, network and data transmission cables.

Composite cables are often required for home automation systems. Depending on the required application, special types such as coaxial and optical fiber are also offered in this category.

Industrial settings often have high voltage applications that require the inclusion of power electronics cables. Environments such as offices with many large machines and buildings with installed control systems are typical.

Most wire types can overlap with other classifications, and the exact type you want depends on a variety of variables.

Although most applications are covered by our product line, if you need help choosing the ideal cable, please contact our technical staff, who will be happy to help.

Your comment submitted.