When it comes to electrical wiring, choosing the right materials is crucial in ensuring safety, efficiency, and compliance with building codes. Two common options for protecting and routing electrical wiring in residential, commercial, and industrial settings are flexible metal conduit and MC cable. Understanding the differences between these two options can help you make an informed decision when planning your next electrical installation project.

.

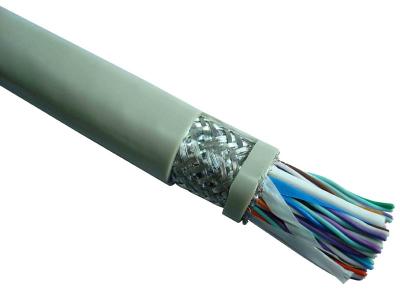

Flexible metal conduit, often referred to as FMC, is a versatile solution that provides protection for electrical wiring in various applications. Made of a flexible metal material such as galvanized steel or aluminum, FMC offers a high level of durability and resistance to corrosion. Its flexibility allows for easy installation in tight or curved spaces, making it well-suited for projects where traditional rigid metal conduit may not be practical. One of the key advantages of flexible metal conduit is its ability to provide mechanical protection for electrical wires while still allowing for flexibility in routing. This can be especially useful in situations where wiring needs to navigate around obstacles or make sharp bends. FMC is also known for its ease of installation, as it can be cut to length with simple tools and does not require specialized bending equipment. In contrast, MC cable, short for metal-clad cable, is a preassembled wiring system that combines the benefits of a metallic sheath with insulated conductors. This type of cable consists of one or more insulated wires surrounded by a corrugated metal sheath, providing both mechanical protection and grounding. MC cable is often used in applications where a high degree of durability is required, such as in exposed or hazardous environments. One of the primary advantages of MC cable is its all-in-one design, which eliminates the need for separate conduit and wiring components. This can result in faster and more straightforward installations, saving both time and labor costs. Additionally, MC cable is often preferred in applications where the wiring needs to be easily accessible for maintenance or modifications, as the metal sheath can be quickly removed to access the insulated conductors.

Flexible metal conduit, often referred to as FMC, is a versatile solution that provides protection for electrical wiring in various applications. Made of a flexible metal material such as galvanized steel or aluminum, FMC offers a high level of durability and resistance to corrosion. Its flexibility allows for easy installation in tight or curved spaces, making it well-suited for projects where traditional rigid metal conduit may not be practical. One of the key advantages of flexible metal conduit is its ability to provide mechanical protection for electrical wires while still allowing for flexibility in routing. This can be especially useful in situations where wiring needs to navigate around obstacles or make sharp bends. FMC is also known for its ease of installation, as it can be cut to length with simple tools and does not require specialized bending equipment. In contrast, MC cable, short for metal-clad cable, is a preassembled wiring system that combines the benefits of a metallic sheath with insulated conductors. This type of cable consists of one or more insulated wires surrounded by a corrugated metal sheath, providing both mechanical protection and grounding. MC cable is often used in applications where a high degree of durability is required, such as in exposed or hazardous environments. One of the primary advantages of MC cable is its all-in-one design, which eliminates the need for separate conduit and wiring components. This can result in faster and more straightforward installations, saving both time and labor costs. Additionally, MC cable is often preferred in applications where the wiring needs to be easily accessible for maintenance or modifications, as the metal sheath can be quickly removed to access the insulated conductors.

..

When comparing flexible metal conduit and MC cable, there are several factors to consider in order to determine which option is best suited for your project. One important consideration is the level of protection required for the wiring system. While both FMC and MC cable offer some degree of mechanical protection, MC cable generally provides a higher level of durability and resistance to damage from environmental factors. Another factor to consider is the ease of installation and flexibility of the wiring system. Flexible metal conduit is well-known for its adaptability to challenging installation environments, while MC cable offers the convenience of a preassembled wiring system that can save time and labor during installation. Understanding the specific requirements of your project will help you determine which solution is the best fit for your needs. In terms of cost, both FMC and MC cable are competitively priced options for protecting and routing electrical wiring. While the initial cost of MC cable may be slightly higher due to its preassembled nature, the time and labor savings that it offers during installation can help offset this difference. On the other hand, flexible metal conduit may be a more cost-effective solution for projects that require a high degree of flexibility and customization in routing the wiring system. In conclusion, both flexible metal conduit and MC cable are reliable options for protecting and routing electrical wiring in a variety of applications. The choice between these two solutions will depend on the specific requirements of your project, including the level of mechanical protection needed, the ease of installation, and the overall cost considerations. By carefully evaluating these factors, you can select the option that best meets your needs and ensures a safe and efficient electrical wiring installation. Furthermore, it’s important to consider the environmental conditions in which the electrical wiring will be installed when choosing between flexible metal conduit and MC cable. Flexible metal conduit is well-suited for installations where there may be exposure to moisture, chemicals, or extreme temperatures, as its metal construction provides excellent resistance to these elements.

When comparing flexible metal conduit and MC cable, there are several factors to consider in order to determine which option is best suited for your project. One important consideration is the level of protection required for the wiring system. While both FMC and MC cable offer some degree of mechanical protection, MC cable generally provides a higher level of durability and resistance to damage from environmental factors. Another factor to consider is the ease of installation and flexibility of the wiring system. Flexible metal conduit is well-known for its adaptability to challenging installation environments, while MC cable offers the convenience of a preassembled wiring system that can save time and labor during installation. Understanding the specific requirements of your project will help you determine which solution is the best fit for your needs. In terms of cost, both FMC and MC cable are competitively priced options for protecting and routing electrical wiring. While the initial cost of MC cable may be slightly higher due to its preassembled nature, the time and labor savings that it offers during installation can help offset this difference. On the other hand, flexible metal conduit may be a more cost-effective solution for projects that require a high degree of flexibility and customization in routing the wiring system. In conclusion, both flexible metal conduit and MC cable are reliable options for protecting and routing electrical wiring in a variety of applications. The choice between these two solutions will depend on the specific requirements of your project, including the level of mechanical protection needed, the ease of installation, and the overall cost considerations. By carefully evaluating these factors, you can select the option that best meets your needs and ensures a safe and efficient electrical wiring installation. Furthermore, it’s important to consider the environmental conditions in which the electrical wiring will be installed when choosing between flexible metal conduit and MC cable. Flexible metal conduit is well-suited for installations where there may be exposure to moisture, chemicals, or extreme temperatures, as its metal construction provides excellent resistance to these elements.

…

On the other hand, MC cable’s metal-clad design offers superior protection against physical damage and can be a preferred choice for installations in areas where the wiring may be subject to impact or abrasion. When it comes to flexibility and adaptability, flexible metal conduit shines in its ability to easily maneuver around obstacles and tight spaces. This flexibility makes it a popular choice for projects where the wiring may need to navigate complex routes or tight corners. In contrast, MC cable’s rigid construction may be less ideal for applications that require a high degree of flexibility in routing the wiring system. For installers looking to minimize installation time and labor costs, MC cable’s preassembled design can offer significant advantages. The all-in-one construction of MC cable eliminates the need to install separate conduit and wiring components, streamlining the installation process and reducing the potential for errors. This can be particularly beneficial for large-scale projects or installations that require a high level of efficiency. On the other hand, flexible metal conduit provides installers with the flexibility to customize the routing of the wiring system on-site. Its ability to be easily cut to length and bent by hand makes it a versatile option for installations that require a high level of customization. While this flexibility may require more time and effort during installation compared to MC cable, it can be a valuable feature for projects with unique layout requirements. In terms of compliance with building codes and regulations, both flexible metal conduit and MC cable are recognized wiring methods that meet industry standards for safety and performance. However, it’s essential to ensure that the specific product you choose is approved for use in your region and complies with local building codes. Consulting with a qualified electrician or building inspector can help ensure that your electrical installation meets all necessary requirements. In conclusion, the choice between flexible metal conduit and MC cable ultimately comes down to meeting the specific needs of your electrical installation project. Both options offer unique advantages in terms of durability, flexibility, ease of installation, and compliance with building codes. By carefully evaluating the requirements of your project and considering factors such as protection, flexibility, installation efficiency, and compliance, you can select the option that best fits your needs and ensures a safe and reliable electrical wiring system.

On the other hand, MC cable’s metal-clad design offers superior protection against physical damage and can be a preferred choice for installations in areas where the wiring may be subject to impact or abrasion. When it comes to flexibility and adaptability, flexible metal conduit shines in its ability to easily maneuver around obstacles and tight spaces. This flexibility makes it a popular choice for projects where the wiring may need to navigate complex routes or tight corners. In contrast, MC cable’s rigid construction may be less ideal for applications that require a high degree of flexibility in routing the wiring system. For installers looking to minimize installation time and labor costs, MC cable’s preassembled design can offer significant advantages. The all-in-one construction of MC cable eliminates the need to install separate conduit and wiring components, streamlining the installation process and reducing the potential for errors. This can be particularly beneficial for large-scale projects or installations that require a high level of efficiency. On the other hand, flexible metal conduit provides installers with the flexibility to customize the routing of the wiring system on-site. Its ability to be easily cut to length and bent by hand makes it a versatile option for installations that require a high level of customization. While this flexibility may require more time and effort during installation compared to MC cable, it can be a valuable feature for projects with unique layout requirements. In terms of compliance with building codes and regulations, both flexible metal conduit and MC cable are recognized wiring methods that meet industry standards for safety and performance. However, it’s essential to ensure that the specific product you choose is approved for use in your region and complies with local building codes. Consulting with a qualified electrician or building inspector can help ensure that your electrical installation meets all necessary requirements. In conclusion, the choice between flexible metal conduit and MC cable ultimately comes down to meeting the specific needs of your electrical installation project. Both options offer unique advantages in terms of durability, flexibility, ease of installation, and compliance with building codes. By carefully evaluating the requirements of your project and considering factors such as protection, flexibility, installation efficiency, and compliance, you can select the option that best fits your needs and ensures a safe and reliable electrical wiring system.

Your comment submitted.