Galvanized steel and aluminum are widely used in data transmission and power transmission cables.

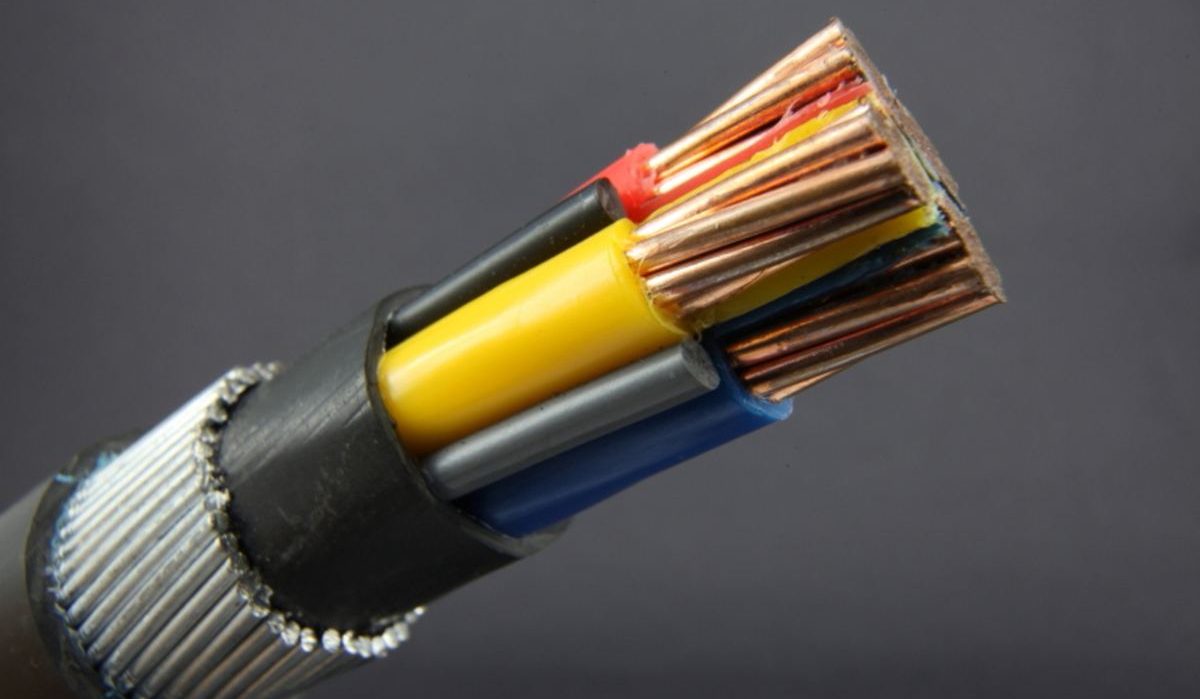

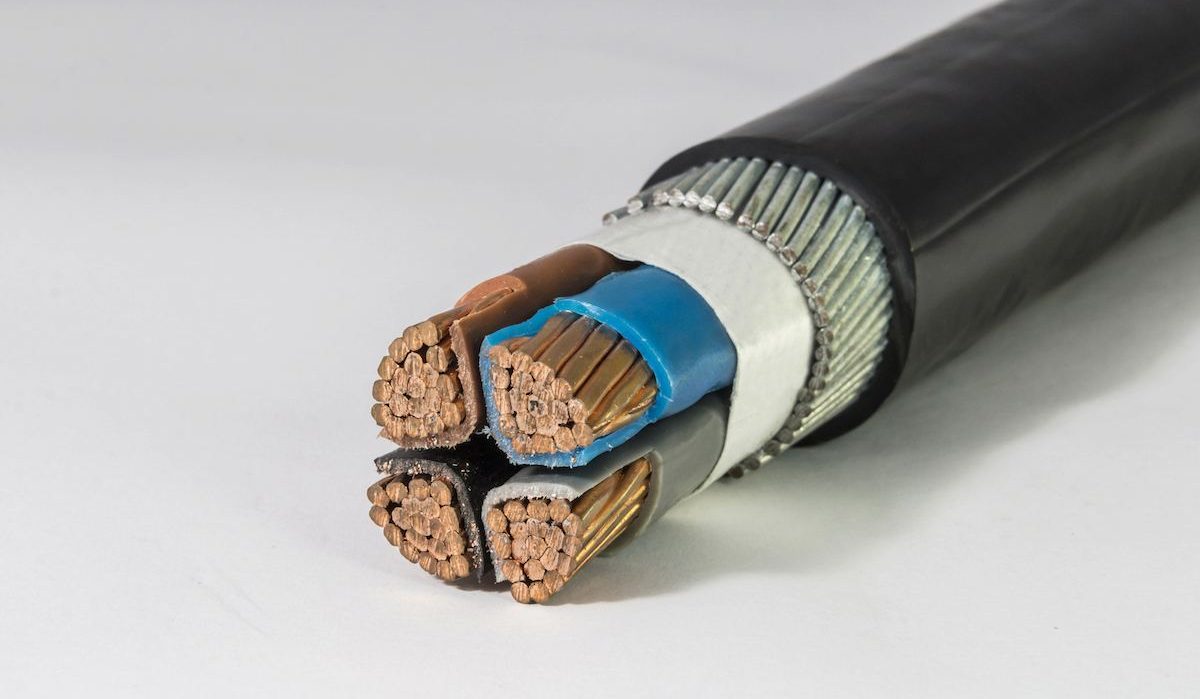

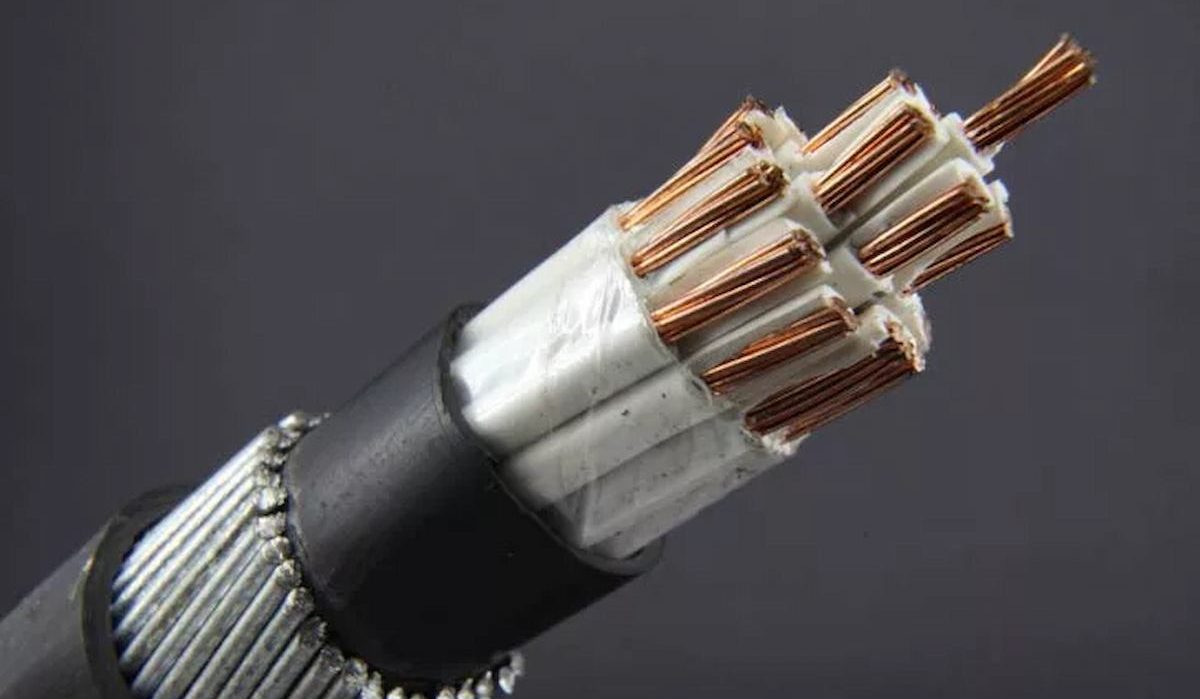

To increase durability, the armored cable has a sheath of wire or tape reinforced with galvanized steel or aluminum alloy.

It is reasonable to anticipate the hazards associated with armored cables, such as shock or pressure from external sources, given the environment in which they are used.

For this reason, an uninterrupted layer of the previously discussed alloys is wrapped around the inner wires of the armored cable to extend its useful life and increase its tensile strength.

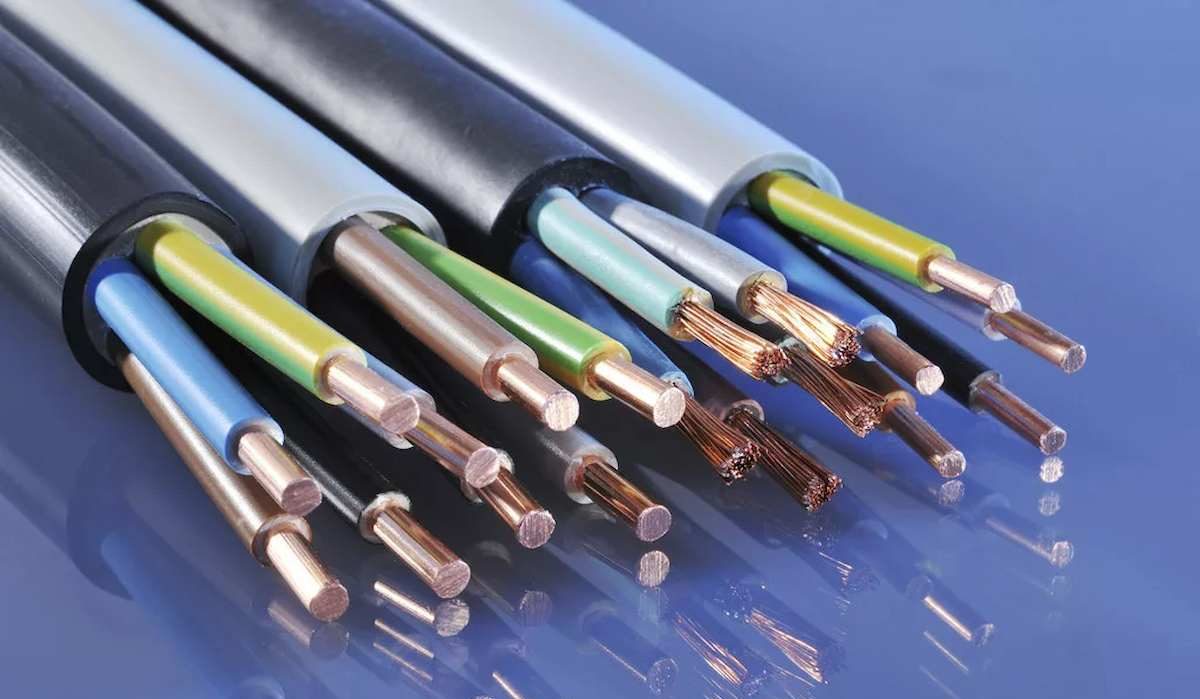

In multi-stranded cables, the shielding layer is usually made of steel, but in single-stranded cables, the shielding layer is usually made of aluminum.

Since steel and aluminum respond differently to the presence of a magnetic field, many alloys have been used in the construction of the shielding layer.

It should be remembered that aluminum alloys are not magnetic and due to this property they are not affected by magnetic fields.

The use of armored cables in urban high voltage distribution networks is the main use of armored cables, and the existence of armored cables helps to prevent various problems.

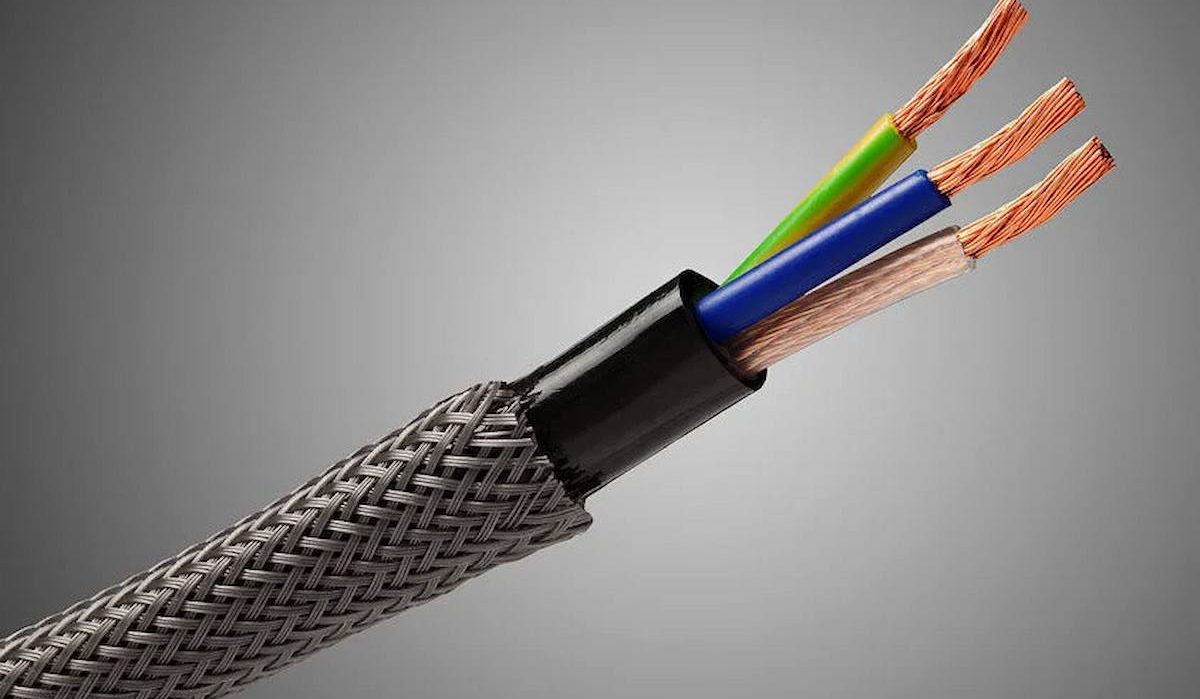

Due to the way these cables are made, the conductor, which is one of their main components and is usually copper wire in these cables and aluminum in the form of high voltage transmission cables, is one of the most important parts of these cables. .

In the manufacture of armored cables, the insulation is often made of PVC, but if moisture insulation and electrical resistance are required, XLPE insulation is used instead.

Polyvinyl chloride, which forms the base layer, acts as a protective barrier between the insulating layer and the layer that is exposed to the environment. Cable armor is an additional important structure of these wires.

Cable armor is a protective layer that protects the cable against high voltages.

In multi-strand cables, the cable armor is usually made of steel, while the cable armor used in single-strand cables is usually made of aluminum.

It is important to note that the type of layer that is placed on the primary insulation of the cable, which is also referred to as the lead sheath, always separates the two components of these cables from each other.

Different types of armored cables

NYRY and N2XRY are two types of weak tension cables that have reinforcing steel wire.

Low voltage armored wires, including NYBY and N2XBY.

Medium voltage cables reinforced with steel wire are indicated by the following part numbers: N2XSYRY, NA2XSYRY, N2XSEYRY and NA2XSEYRY.

Armored cables for medium voltage: N2XSYBY, N2XSEYBY, NA2XSYBY and NA2XSEYBY

SWA and STA are both types of steel armored multicore cables.

AWA and ATA are both types of aluminum armored single core cables.

Applications involving armored cables or armored cables themselves

Due to the high electrical resistance of this type of cable, it is usually installed in potentially hazardous locations.

For example, it may be used in places that are dirty, greasy, damp or even infested with rodents.

On the other hand, it may be argued that the oil and gas industry as well as the petrochemical industry are the most common users of these cables.

It should be noted that the armored cable is safe against voltage and shock and also protects mice from destroying the wire.

Special glands are used to connect these types of cables and other parts of the device.

It is also important to mention that this type of wire and cable is used for fixed installation inside and outside the building in basements, in water, pipes and cables, as well as in open places that require a significant amount. Mechanical protection

Cable armor is a metal covering wrapped around the outside of the cable to protect it from mechanical stress.

Its primary use is in hazardous situations that require an additional layer of cable protection or in settings where the National Electrical Code requires the use of MC (metal sheath) type cable.

Both of these scenarios are common.

Thanks to the armor made of metal, the cable is protected from falling objects, crushing and other forms of physical damage.

Additionally, it offers better fire resistance, makes electrical maintenance work safer, and may be run in riser as well as plenum applications.

Armor allows almost any type of electrical cable installation, which is useful even in areas with strict building codes.

Materials commonly used in cable armor

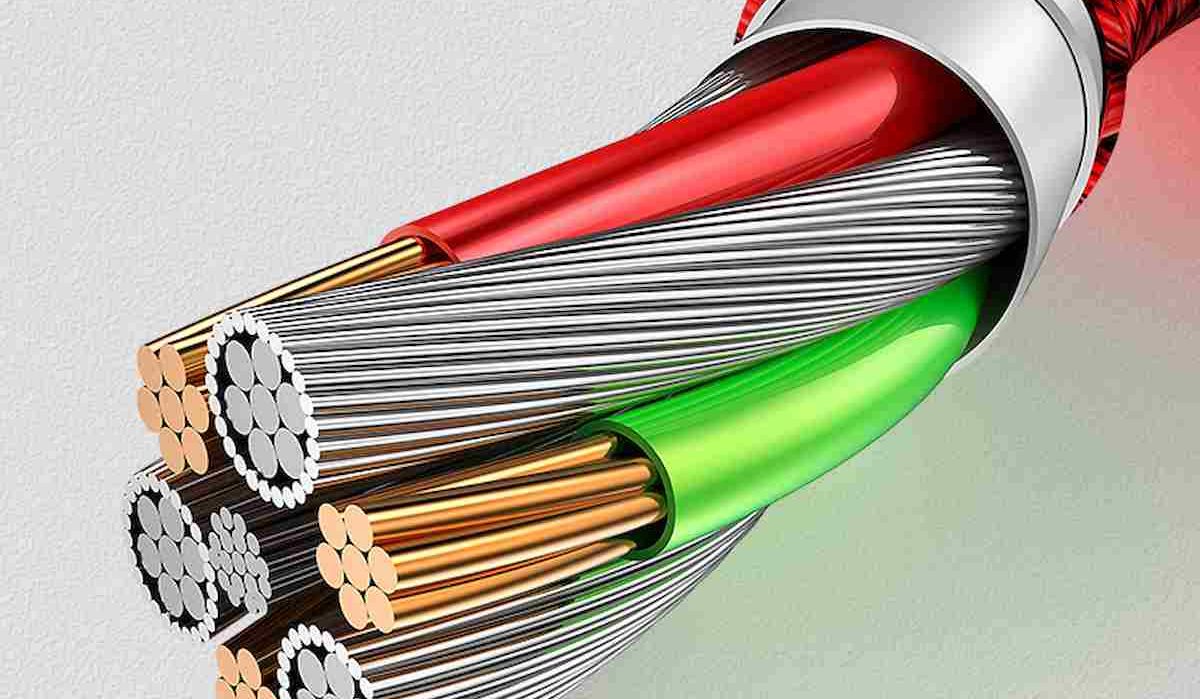

Interlocking galvanized steel, interlocking aluminum, and corrugated and welded aluminum are the three most commonly used types of armor.

Both steel and aluminum armor are equally adequate for most uses and are comparable in price.

However, there are a few distinct features that set them apart and can make one of them more suitable for a particular application.

Steel is a material that can withstand crushing as well as impact. However, despite being stronger, it is between 10 and 40 percent heavier than aluminum.

When it comes to high current applications, steel is superior to aluminum in resisting electromagnetic interference.

Aluminum: Despite being nearly five times more conductive than steel, aluminum armor is significantly lighter than steel armor.

Although aluminum armor can withstand impacts, aluminum armor must be five millimeters thicker than steel armor to have the same crushing resistance as steel.

When used in low current conditions, aluminum provides a superior electromagnetic interference shield for the cable.

Comparing armor with protection

Armor and protection are concepts that often go hand in hand. Even though both are metal layers used in cables for protection, the protection they provide is very different from each other.

Armor is a resistant covering of metal designed to protect the mechanical integrity of the cable.

It is wrapped around the outside of the cable. It protects the cable from any potential physical threats and protects it from being damaged by external forces that may exert pressure on it.

The inner layers of the cable, especially those surrounding the conductor, are shielded.

It does its best to reduce electromagnetic interference, preventing the cable from receiving currents or signals from the outside world, both of which have the potential to degrade its performance.

The application for which a cable is developed determines whether both armor and shielding are used in the cable.

We offer a wide range of wires and cables with our product pricing policy in line with global market prices.

You can easily contact us and be sure that you will get a relatively lower price than the market. So, fill out the application form, let us know what you need and we’ll get back to you in no time.

Your comment submitted.