One of the biggest services that wires and cables provide to communities is the transmission of electrical power required by industrial machines in factories, considering the importance of the performance that these types of cables provide and must be provided with standard quality to meet industrial needs.

Diameter

The diameter of the wire affects the amount of electricity it can pass through. The larger the diameter, the higher the amperage. The smaller the current, the smaller the diameter. You need enough amps to power your lights and fans without electricity. Heating Wire As a small matter, if your lights and fans are powered by 12 gauge (0.12 inch) wire, you will need at least a 6 amp power supply. However, you should always check with your local electrician before using any wire.

measure

Specifications refer to the thickness of the wire. There are three different types of meters, each with a specific function. The first component is aluminum wire. Aluminum wire is often used for ceiling lighting and fans. It is cheap and durable. Aluminum wire does not conduct electricity efficiently, so if you are using aluminum wire to wire your lights, you will need to add more cable and copper wire. Copper wire is more conductive and cheaper than aluminum wire because it is thicker. However, it is difficult to bend and breaks quickly. The third wire is made of steel. The wire is the strongest and most flexible wire available. In addition, it is very expensive, so it is only recommended for professional growers who plan extensive wiring projects.

Outstanding shares

It shows the value of clustered single strings. For example, two strands are made up of two separate wires twisted together. Three strands of wire are twisted together. Four strands of wire are twisted together. Consider the length of the project when estimating the amount of wire needed. If you are building a greenhouse, you may need to purchase additional cables to cover the entire roof surface. If you are only installing a few lights in one part of your yard, you can save money by buying less wire.

industrial cable types

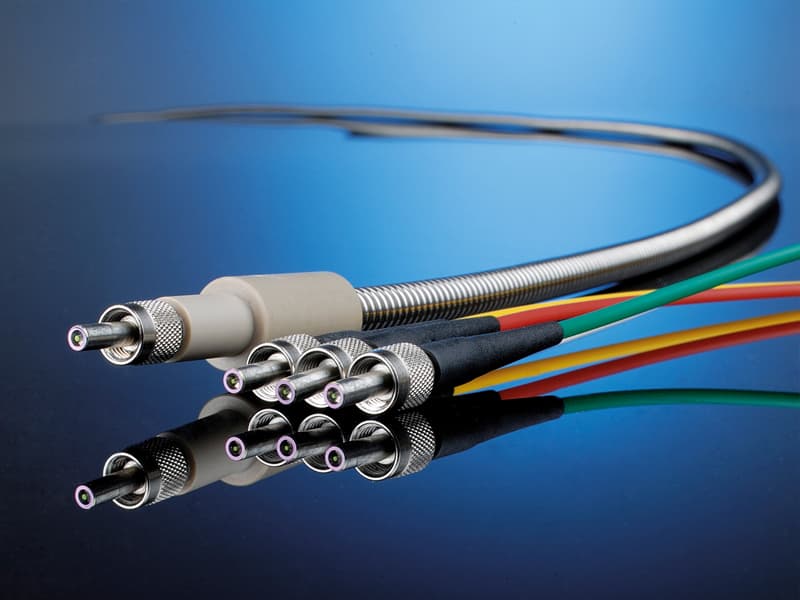

In industrial applications, there are different types of cables including coaxial, twin, triple and quad cables. These cables are designed to meet specific application requirements and criteria.

This video explains the difference between these different cables and how to use them in different parts.

Different types of cables are used in industrial applications. Each type is designed for a specific function and has its own advantages and disadvantages. Knowing which type is optimal for each type may help you choose the right cable for your application.

All kinds of industrial wires

Copper and aluminum are two widely used materials of industrial cable. Both have their advantages and disadvantages. Copper is an excellent conductor of current, however aluminum is significantly stronger than copper and an excellent conductor of large currents. However, neither material is ideal for long-term use due to its susceptibility to corrosion

Aluminum cable

Aluminum cables are strong and durable, but not suitable for carrying large currents. In addition, aluminum is malleable and a poor conductor of electricity. Ideal for connecting small devices, motors and switches.

copper cable

Copper wires are excellent at carrying strong currents. It is also highly flexible and resistant to corrosion. Copper is an excellent conductor for machinery, tools and equipment. Due to its compatibility, it can also be used to suspend loads.

Electromagnetic fiber

Optical fibers are used to transmit information over long distances. To prevent breakage, fiber optic cables are made of glass and covered with plastic. Very expensive fiber optic cables are used only when absolute reliability is required.

Inflatable wiring

Wiring in office buildings, shopping centers and warehouses uses plenum wiring. In such configurations, plenum cables are often installed on ceiling tiles. These cables are designed to be resistant to water, ignition and electromagnetic interference (EMI).

PVC wiring

PVC cables are usually used for general wiring and are economical. PVC is also waterproof, non-flammable and requires little maintenance. PVC cable is commonly used for electricity distribution and telecommunications.

industrial electrical cable

As a complete definition for power cable used in industrial applications; It can be said that any type of wire intended to transmit electricity from one place to another can be classified as industrial cables.

There are different types of industrial cables such as single core cables, multi core cables and coaxial cables among many others.

In addition, depending on the application, there are different types of industrial power cables, and industrial power cables are commonly used in factories, warehouses, power plants, and other types of businesses and organizations.

Why do we have a requirement for them?

Industrial power lines both help maintain a healthy environment and protect us from potentially dangerous radiation. In most cases, these are used in areas where human exposure to radio frequency (RF) signals could be potentially harmful. In addition, electricity can be transferred through these lines between different electronic devices for no particular purpose. That which interferes or interferes.

How exactly do they work?

Industrial wire and cable have the same purpose as normal household wiring. Insulation surrounds each of the wires in the cable to prevent current from passing through each of them. When two or more wires need to be connected together, a connector is attached to each end of the cables. When wires are connected together, they form a single entity.

Where are they used?

Below are examples of common applications for industrial cables:

– Provides power for electronic devices such as televisions, computers and stereos

– To be responsible for the operation of all mechanical, lighting and heating systems

– Be careful of machines

– Data transmission

Can I use these in my home?

Yeah! Most of the electrical cables used in homes are also used in commercial and industrial environments. However, some have been modified so that they can be safely used indoors. Before using these cables indoors, you should always check the safety requirements first.

electrical cable types list

With a wide range of applications in industry, home and other sectors, today cable and electric wire come in many categories and types, a list of common types of cables is provided in the following section.

Type 1 (cable)

This particular type of cable is used in a wide variety of different electrical applications. In this example, a conductor is produced by twisting two separate wires together. This type of wire is both flexible and strong and is often used in the process of connecting various devices to the electrical outlet.

type 2 (wire)

Stranded wire is another name for this particular type of wire. It consists of several thin metal wires twisted together. In applications where the wire is subjected to high tensile stresses, this type of wire is suitable due to its greater strength than solid wire.

Type 4 (soft wire)

This type of wiring is made to bend without breaking because it can withstand the stress. It is used in certain settings where wires are often bent.

Type 5 (solid wire)

This type is comparable to type 2 in many ways. However, it has a very noticeable and firm consistency. Works great for applications where wires are unlikely to bend or bend.

Type 6 (bare wire)

This form of wire is used in situations where the insulation must be removed. Applications that do not require protection are common examples of where they are used.

Type 8 (shielded cable)

The signal that is being transmitted should not be disturbed by other signals that may exist in the surrounding environment, that is why shielded cables are used. The shielding effect can be achieved by wrapping metal foil around the cable conductors.

Type 9 (RJ-45 connector)

Typically, a coaxial cable is inserted into this socket to connect it to a device. This ratio, shape and size are typical.

Your comment submitted.