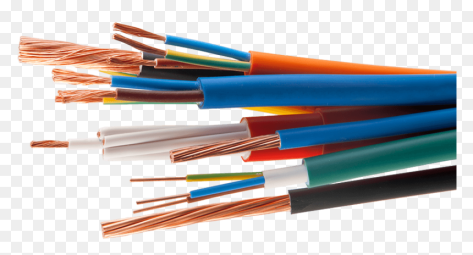

Low voltage electrical cables are an essential component of any electrical system, providing the necessary connection between power sources and various electrical devices. These cables are designed to carry low voltage electricity safely and efficiently, making them a crucial part of residential, commercial, and industrial electrical systems. When it comes to low voltage electrical cables, there are several key factors to consider, including the type of cable, its specifications, and its intended application. Understanding these factors can help you make an informed decision when selecting the right low voltage electrical cable for your specific needs. One of the most important considerations when choosing a low voltage electrical cable is the type of cable construction. There are several different types of low voltage electrical cables available, each with its own unique characteristics and advantages. Some of the most common types of low voltage electrical cables include: 1. PVC Insulated Cables: PVC insulated cables are a popular choice for low voltage applications due to their flexibility, durability, and cost-effectiveness. These cables are made with a polyvinyl chloride (PVC) insulation that provides good protection against moisture, abrasion, and chemicals. 2. XLPE Insulated Cables: Cross-linked polyethylene (XLPE) insulated cables are another common type of low voltage electrical cable that is known for its excellent electrical properties and thermal stability. XLPE insulated cables are often used in outdoor and underground applications where higher temperature ratings are required.

.

3. Rubber Insulated Cables: Rubber insulated cables are widely used in industrial applications due to their high flexibility and resistance to oils, greases, and solvents. These cables are ideal for environments where mechanical stress and abrasion are common. 4. Control Cables: Control cables are specially designed for transmitting control signals in various industrial automation systems. These cables are often used in motor control circuits, sensors, and other applications that require precise signal transmission. In addition to the type of cable construction, it is also important to consider the specifications of the low voltage electrical cable, including its voltage rating, current-carrying capacity, insulation material, and conductor size. These specifications play a crucial role in determining the performance and safety of the cable in a specific application. When selecting a low voltage electrical cable, it is essential to choose a cable with the appropriate voltage rating to ensure safe and reliable operation. The voltage rating of the cable should match the voltage of the electrical system to which it will be connected. Using a cable with a lower voltage rating than the system voltage can lead to overheating and potential safety hazards. In addition to the voltage rating, the current-carrying capacity of the cable is another important factor to consider. The current-carrying capacity of a cable is determined by its conductor size and insulation material, with larger conductor sizes and high-quality insulation materials allowing the cable to carry higher currents safely. The insulation material used in a low voltage electrical cable plays a crucial role in protecting the conductors from environmental factors such as moisture, heat, and chemicals. High-quality insulation materials like PVC, XLPE, and rubber provide excellent electrical insulation and mechanical protection, ensuring the safe and reliable operation of the cable. The conductor size of a low voltage electrical cable is another important consideration, as it determines the cable’s current-carrying capacity and voltage drop characteristics.

3. Rubber Insulated Cables: Rubber insulated cables are widely used in industrial applications due to their high flexibility and resistance to oils, greases, and solvents. These cables are ideal for environments where mechanical stress and abrasion are common. 4. Control Cables: Control cables are specially designed for transmitting control signals in various industrial automation systems. These cables are often used in motor control circuits, sensors, and other applications that require precise signal transmission. In addition to the type of cable construction, it is also important to consider the specifications of the low voltage electrical cable, including its voltage rating, current-carrying capacity, insulation material, and conductor size. These specifications play a crucial role in determining the performance and safety of the cable in a specific application. When selecting a low voltage electrical cable, it is essential to choose a cable with the appropriate voltage rating to ensure safe and reliable operation. The voltage rating of the cable should match the voltage of the electrical system to which it will be connected. Using a cable with a lower voltage rating than the system voltage can lead to overheating and potential safety hazards. In addition to the voltage rating, the current-carrying capacity of the cable is another important factor to consider. The current-carrying capacity of a cable is determined by its conductor size and insulation material, with larger conductor sizes and high-quality insulation materials allowing the cable to carry higher currents safely. The insulation material used in a low voltage electrical cable plays a crucial role in protecting the conductors from environmental factors such as moisture, heat, and chemicals. High-quality insulation materials like PVC, XLPE, and rubber provide excellent electrical insulation and mechanical protection, ensuring the safe and reliable operation of the cable. The conductor size of a low voltage electrical cable is another important consideration, as it determines the cable’s current-carrying capacity and voltage drop characteristics.

..

Choosing the right conductor size for a specific application is essential to ensure optimal performance and efficiency. When selecting a low voltage electrical cable, it is also important to consider the specific application requirements, such as the installation environment, temperature rating, and mechanical stresses that the cable will be subjected to. For outdoor and underground applications, cables with UV-resistant insulation and moisture-resistant properties are recommended to ensure long-term durability and reliability. In industrial settings where cables are exposed to mechanical stress and abrasion, cables with high flexibility and robust construction are ideal to withstand harsh operating conditions. Additionally, using armored cables or cables with additional protective layers can provide enhanced mechanical protection and resistance to impact damage. Overall, choosing the right low voltage electrical cable is essential to ensure the safety, reliability, and efficiency of your electrical system. By considering factors such as cable construction, specifications, and application requirements, you can select a cable that meets your specific needs and provides optimal performance in various electrical applications. Furthermore, the installation of low voltage electrical cables plays a critical role in ensuring the overall performance and safety of the electrical system. Proper cable installation practices are essential to prevent issues such as overheating, voltage drop, and electrical faults that can lead to equipment damage and safety hazards. Before installing low voltage electrical cables, it is important to carefully plan the cable routing and layout to minimize cable lengths and avoid sharp bends or kinks that can cause damage to the cable insulation. Proper support and bundling of cables are also essential to prevent sagging and ensure good cable management within the electrical system. When installing low voltage electrical cables, it is important to observe the recommended bending radius of the cable to prevent damage to the insulation and conductors. Bending the cable beyond its specified radius can lead to insulation cracking, conductor breakage, and potential electrical faults, compromising the safety and performance of the cable.

Choosing the right conductor size for a specific application is essential to ensure optimal performance and efficiency. When selecting a low voltage electrical cable, it is also important to consider the specific application requirements, such as the installation environment, temperature rating, and mechanical stresses that the cable will be subjected to. For outdoor and underground applications, cables with UV-resistant insulation and moisture-resistant properties are recommended to ensure long-term durability and reliability. In industrial settings where cables are exposed to mechanical stress and abrasion, cables with high flexibility and robust construction are ideal to withstand harsh operating conditions. Additionally, using armored cables or cables with additional protective layers can provide enhanced mechanical protection and resistance to impact damage. Overall, choosing the right low voltage electrical cable is essential to ensure the safety, reliability, and efficiency of your electrical system. By considering factors such as cable construction, specifications, and application requirements, you can select a cable that meets your specific needs and provides optimal performance in various electrical applications. Furthermore, the installation of low voltage electrical cables plays a critical role in ensuring the overall performance and safety of the electrical system. Proper cable installation practices are essential to prevent issues such as overheating, voltage drop, and electrical faults that can lead to equipment damage and safety hazards. Before installing low voltage electrical cables, it is important to carefully plan the cable routing and layout to minimize cable lengths and avoid sharp bends or kinks that can cause damage to the cable insulation. Proper support and bundling of cables are also essential to prevent sagging and ensure good cable management within the electrical system. When installing low voltage electrical cables, it is important to observe the recommended bending radius of the cable to prevent damage to the insulation and conductors. Bending the cable beyond its specified radius can lead to insulation cracking, conductor breakage, and potential electrical faults, compromising the safety and performance of the cable.

…

Proper cable termination and splicing techniques are vital to ensure reliable electrical connections and prevent issues such as loose connections, overheating, and short circuits. Using high-quality cable connectors, terminals, and junction boxes can help maintain secure electrical connections and minimize the risk of electrical faults during operation. In addition to proper installation practices, regular inspection and maintenance of low voltage electrical cables are essential to identify potential issues early and prevent unexpected failures in the electrical system. Visual inspections of cables for signs of damage, wear, or corrosion can help detect problems before they escalate and ensure the continued safe operation of the system. In conclusion, low voltage electrical cables are a fundamental component of electrical systems, providing the necessary connection between power sources and electrical devices. When choosing a low voltage electrical cable, it is important to consider factors such as cable construction, specifications, and application requirements to ensure safe and reliable operation. By selecting the right cable type, voltage rating, current-carrying capacity, and insulation material, you can ensure optimal performance and efficiency in various electrical applications. Proper installation, termination, and maintenance practices are also essential to maximize the lifespan of low voltage electrical cables and prevent issues that can compromise the safety and reliability of the electrical system. Overall, investing in high-quality low voltage electrical cables and adhering to best practices in cable installation and maintenance can help you achieve a safe, efficient, and reliable electrical system for your residential, commercial, or industrial needs. Remember, when it comes to low voltage electrical cables, prioritizing quality, safety, and performance is key to successful electrical installations and operations. Choose the right cables, follow best practices, and conduct regular maintenance to ensure the longevity and reliability of your electrical system.

Proper cable termination and splicing techniques are vital to ensure reliable electrical connections and prevent issues such as loose connections, overheating, and short circuits. Using high-quality cable connectors, terminals, and junction boxes can help maintain secure electrical connections and minimize the risk of electrical faults during operation. In addition to proper installation practices, regular inspection and maintenance of low voltage electrical cables are essential to identify potential issues early and prevent unexpected failures in the electrical system. Visual inspections of cables for signs of damage, wear, or corrosion can help detect problems before they escalate and ensure the continued safe operation of the system. In conclusion, low voltage electrical cables are a fundamental component of electrical systems, providing the necessary connection between power sources and electrical devices. When choosing a low voltage electrical cable, it is important to consider factors such as cable construction, specifications, and application requirements to ensure safe and reliable operation. By selecting the right cable type, voltage rating, current-carrying capacity, and insulation material, you can ensure optimal performance and efficiency in various electrical applications. Proper installation, termination, and maintenance practices are also essential to maximize the lifespan of low voltage electrical cables and prevent issues that can compromise the safety and reliability of the electrical system. Overall, investing in high-quality low voltage electrical cables and adhering to best practices in cable installation and maintenance can help you achieve a safe, efficient, and reliable electrical system for your residential, commercial, or industrial needs. Remember, when it comes to low voltage electrical cables, prioritizing quality, safety, and performance is key to successful electrical installations and operations. Choose the right cables, follow best practices, and conduct regular maintenance to ensure the longevity and reliability of your electrical system.

Your comment submitted.