One unique use of wire and cable, usually of the low-voltage, high-voltage variety, is in the electrical system of neon signs to provide the power needed to make the neon glow.

A light display known as a neon sign is created by bending gas-filled glass tubes into letters or other patterns for decorative purposes. The gas in the tube is what causes the light to turn on when a high voltage current is passed through it.

Although neon was first used in the production of these signs, a variety of other gases were also used. The combination of these gases and the various colors and phosphor coatings applied to the glass tubes results in the production of more than fifty distinct colors across the spectrum.

The development of neon signs can be traced back to scientific experiments in which various gases were exposed to high voltage currents. In 1856, Heinrich Geisler invented a light source by sending a high-voltage alternating current through a gas contained in a low-pressure glass tube.

Later experiments showed that almost all gases are capable of conducting electricity, and many of them produce visible light. The problem is that most common gases, such as carbon dioxide, react with the live electrodes in the sealed tube. This leads to a rapid decrease in the efficiency of the electrodes, which continues until the light is completely ejected.

Sir William Ramsay and Morris William Travers in 1898 proposed a process for the fractional distillation of liquid air. During this process, the elements neon, argon, krypton and xenon, which are considered noble gases, were found.

By enclosing these gases in glass tubes and sealing them, they were able to produce a range of colored light sources ranging from the vibrant red-orange of neon to the intense blue-gray or violet of argon. These gases not only emit colored light, but are also chemically inert and do not react with electrodes.

The liquid air fractionation process remained too expensive until 1907, when it was developed by Georges Claude in France and Carl von Linde in Germany that a more economical method could be used instead. Initially, Georges Claude was interested in producing large quantities of oxygen for use in hospitals and other industrial settings.

Claude is looking for possible uses for the noble gases that are produced as a byproduct of this distillation process, even if there is no clear market for them. He began popularizing illuminated signs that used neon-filled tubes, inspired by earlier experimental work done by Ramsay and Travers.

In 1910, he exhibited his first neon sign at an exhibition in Paris, and the following year, in 1912, he made his first neon sign for commercial use. In 1915, when business was booming, he founded the Claude Neon Sign Company and began offering royalties to prospective owners.

In 1923, a Los Angeles car dealer named Earl C. Anthony bought two Claude neon signs for his Packard dealership. This was the first time neon signs were used in the United States.

During the 1920s and 1930s, neon tubes were used for a variety of purposes, including decorative displays and signs. As a result, many buildings began to use neon tubes in their architecture. In 1947, a number of casinos in Las Vegas attracted attention with flashy neon signs.

Plastic signs lit from the inside with fluorescent tubes gradually replaced neon signs in the 1950s and 1960s. In both the realm of commercial signage and the art medium, neon has recently seen a resurgence in popularity. The Neon Art Museum is located in Los Angeles and houses historical and contemporary works of neon art.

Low voltage cable for neon signs

For neon lighting in advertising boards, different types of cables are needed, from low pressure to high pressure.

Neon gas was once used in the production of neon signs. However, it is currently used exclusively in the production of red and orange colors. The vast majority of signs use argon or a combination of argon and neon. A small amount of mercury is mixed with argon gas to produce a brilliant blue light.

This method is done in order to increase the brightness of the light. Inside the glass tube, this light interacts with a variety of light-emitting phosphors, resulting in the production of a wide range of colors.

Also, light shades are available in different colors. However, if intense blue light is required, the glass can be left in its clear state. Xenon, krypton and helium are occasionally used to achieve special effects with color.

The glass tubes used in neon signs are often made of lead-based glass, which is softer and more flexible. It can be purchased in lengths of 4-5 feet and diameters from 0.3 inches (8 mm) to 1.0 inches (25 mm) (1.2-1.5 meters).

The electrodes at each end of a light-emitting tube are usually made of very pure iron and enclosed in a glass jacket that is either cylindrical or has an opening at one end. After connecting to the metal electrode, the wire was passed through the open end of the glass chamber. The open end of the indicator extends further into the tube, while the closed end is hermetically sealed to the end of the indicator tube.

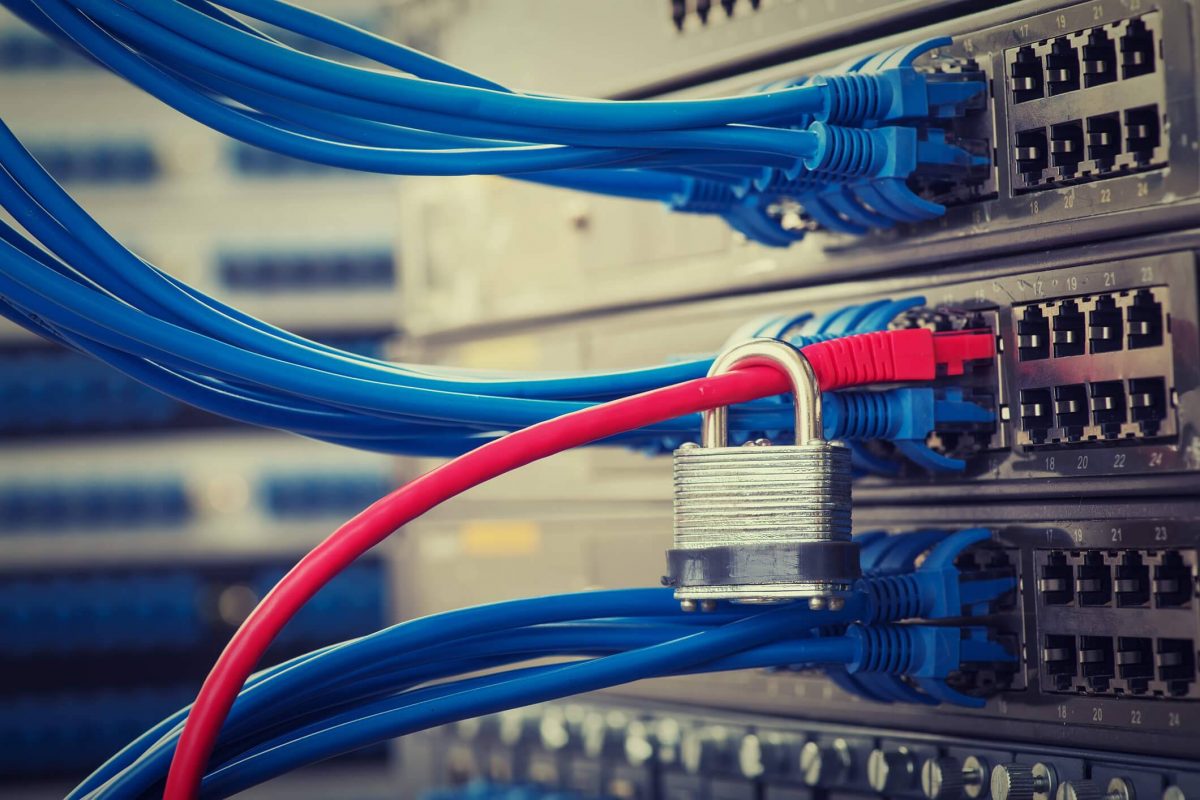

A transformer takes the 120 volts supplied by the wires and converts them to the 15,000 volts needed to power the sign. This high voltage electricity is delivered by a transformer. Current ratings for neon lights are typically between 30 and 60 mA, although current values for transformers are typically twice as high.A unique wire called GTO wire that can withstand a voltage of at least 7500 volts is used to make the connection between the sign electrodes and the transformer. This wire is also used to connect different parts of the light tube to each other in series.

Low voltage wire for neon signs

We discussed the wire and voltage requirements, from low to high, for neon lighting used in billboards. But how to make neon signs is still a question.

Making neon signs is both an art and a mechanical process. With a few exceptions, each logo is unique and must be designed to fit the desired representation within the available space. The diameter of the hose, the minimum radius that the hose can bend, and the total length of hose that the transformer can provide will limit the final design.

For example, the smaller the diameter of the tube, the stronger the light. Conversely, a smaller diameter tube requires more current and limits the total length of tube that the transformer can handle.

Creating a neon sign is largely a manual process. This involves bending the tube and connecting the electrodes, removing any impurities inside the tube, then venting and adding gas.

If neon light is used, the tube should be fully lit within 15 minutes. Argon can last several hours. If you add a small amount of mercury to an argon tube, put a drop in the opening of the tube before sealing the tube. The droplets then roll from one end to the other to coat the electrodes after the aging process.

Any problems, such as flickering in the gas or hot spots on the tube, indicate that the tube should be opened and the bombing and refilling process repeated.

Your comment submitted.