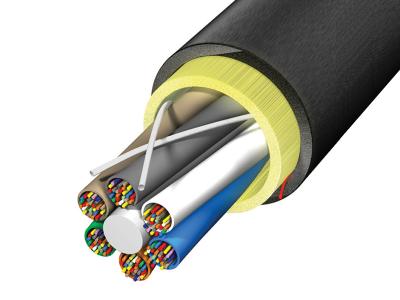

In the world of electrical wiring and power distribution, two commonly used types of cables are armoured cables and XLPE cables. These cables play a crucial role in various applications, providing safe and efficient transmission of electricity. Understanding the differences between armoured cables and XLPE cables can help in making an informed decision when choosing the right type of cable for a particular project. Armoured Cables: Armoured cables are a type of power cable that is commonly used in industrial and commercial applications. These cables are designed to provide mechanical protection and are suitable for installation in both indoor and outdoor environments. The armouring in these cables provides an extra layer of protection, making them resistant to physical damage, moisture, and other environmental factors. One of the key components of armoured cables is the metallic armouring, which can be made of steel or aluminum. This armouring provides protection against external stresses such as impact, abrasion, and crushing. As a result, armoured cables are ideal for use in areas where the cable may be exposed to rough handling or where there is a risk of mechanical damage. Another important aspect of armoured cables is their ability to withstand higher temperatures. These cables are designed to operate at high temperatures without compromising on their performance, making them suitable for use in demanding environments where temperature fluctuations are common.

.

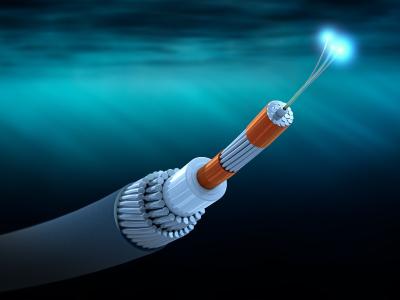

XLPE Cables: Cross-linked polyethylene (XLPE) cables are another popular choice for power transmission and distribution. These cables are known for their excellent electrical properties, including high insulation resistance and low dielectric loss. XLPE cables are also resistant to moisture, chemicals, and environmental factors, making them suitable for a wide range of applications. One of the key advantages of XLPE cables is their flexibility. These cables are easy to bend and manipulate, making them ideal for installations in tight spaces or complex configurations. The flexibility of XLPE cables also reduces the need for joints and connectors, making installation faster and more cost-effective. XLPE cables are also known for their high current-carrying capacity. These cables are designed to handle large amounts of electrical current without overheating, making them a reliable choice for high-power applications. With their low electrical losses and high efficiency, XLPE cables are an energy-efficient option for transmitting electricity over long distances. Comparison: When comparing armoured cables and XLPE cables, several factors come into play that can help in determining the most suitable option for a specific application. One of the key differences between the two types of cables is their construction. Armoured cables have an additional layer of metallic armouring, which provides mechanical protection, while XLPE cables rely on the cross-linked polyethylene insulation for insulation and protection. In terms of durability, armoured cables are known for their rugged construction and resistance to physical damage. These cables are suitable for installations in harsh environments where there is a risk of mechanical stress or impact. XLPE cables, on the other hand, are flexible and lightweight, making them easy to handle and install in various settings. When it comes to temperature resistance, both armoured cables and XLPE cables are designed to withstand high temperatures. However, XLPE cables are known for their excellent thermal properties, which allow them to operate efficiently at elevated temperatures without compromising on performance.

XLPE Cables: Cross-linked polyethylene (XLPE) cables are another popular choice for power transmission and distribution. These cables are known for their excellent electrical properties, including high insulation resistance and low dielectric loss. XLPE cables are also resistant to moisture, chemicals, and environmental factors, making them suitable for a wide range of applications. One of the key advantages of XLPE cables is their flexibility. These cables are easy to bend and manipulate, making them ideal for installations in tight spaces or complex configurations. The flexibility of XLPE cables also reduces the need for joints and connectors, making installation faster and more cost-effective. XLPE cables are also known for their high current-carrying capacity. These cables are designed to handle large amounts of electrical current without overheating, making them a reliable choice for high-power applications. With their low electrical losses and high efficiency, XLPE cables are an energy-efficient option for transmitting electricity over long distances. Comparison: When comparing armoured cables and XLPE cables, several factors come into play that can help in determining the most suitable option for a specific application. One of the key differences between the two types of cables is their construction. Armoured cables have an additional layer of metallic armouring, which provides mechanical protection, while XLPE cables rely on the cross-linked polyethylene insulation for insulation and protection. In terms of durability, armoured cables are known for their rugged construction and resistance to physical damage. These cables are suitable for installations in harsh environments where there is a risk of mechanical stress or impact. XLPE cables, on the other hand, are flexible and lightweight, making them easy to handle and install in various settings. When it comes to temperature resistance, both armoured cables and XLPE cables are designed to withstand high temperatures. However, XLPE cables are known for their excellent thermal properties, which allow them to operate efficiently at elevated temperatures without compromising on performance.

..

This makes XLPE cables a preferred choice for applications that require high-temperature resistance. In terms of cost, armoured cables are generally more expensive than XLPE cables due to the additional layer of armouring. However, the extra cost is justified by the enhanced mechanical protection that armoured cables provide, making them a cost-effective option for installations where durability is a priority. XLPE cables, on the other hand, offer a more economical solution for projects where flexibility and ease of installation are key factors. Conclusion: In conclusion, both armoured cables and XLPE cables have their own set of advantages and are suitable for different applications based on specific requirements. Armoured cables are ideal for installations that require superior mechanical protection and durability, while XLPE cables are a great choice for projects that demand flexibility, high current-carrying capacity, and excellent electrical properties. When choosing between armoured cables and XLPE cables, it is important to consider factors such as the operating environment, temperature requirements, installation constraints, and budget constraints. By understanding the strengths and limitations of each type of cable, you can make an informed decision that meets your project needs and ensures safe and efficient power transmission. Ultimately, the choice between armoured cables and XLPE cables will depend on the unique requirements of your project and the specific conditions in which the cables will be installed. Both types of cables offer reliable performance and durability, making them essential components in electrical systems across various industries. In addition to considering the specific requirements of a project, it is also important to consult with electrical engineers and professionals to assess the most suitable type of cable for the intended application. Their expertise and experience can provide valuable insights into the most effective and efficient solution for power transmission needs. Furthermore, regular maintenance and inspection of both armoured cables and XLPE cables are essential to ensure their continued performance and longevity.

This makes XLPE cables a preferred choice for applications that require high-temperature resistance. In terms of cost, armoured cables are generally more expensive than XLPE cables due to the additional layer of armouring. However, the extra cost is justified by the enhanced mechanical protection that armoured cables provide, making them a cost-effective option for installations where durability is a priority. XLPE cables, on the other hand, offer a more economical solution for projects where flexibility and ease of installation are key factors. Conclusion: In conclusion, both armoured cables and XLPE cables have their own set of advantages and are suitable for different applications based on specific requirements. Armoured cables are ideal for installations that require superior mechanical protection and durability, while XLPE cables are a great choice for projects that demand flexibility, high current-carrying capacity, and excellent electrical properties. When choosing between armoured cables and XLPE cables, it is important to consider factors such as the operating environment, temperature requirements, installation constraints, and budget constraints. By understanding the strengths and limitations of each type of cable, you can make an informed decision that meets your project needs and ensures safe and efficient power transmission. Ultimately, the choice between armoured cables and XLPE cables will depend on the unique requirements of your project and the specific conditions in which the cables will be installed. Both types of cables offer reliable performance and durability, making them essential components in electrical systems across various industries. In addition to considering the specific requirements of a project, it is also important to consult with electrical engineers and professionals to assess the most suitable type of cable for the intended application. Their expertise and experience can provide valuable insights into the most effective and efficient solution for power transmission needs. Furthermore, regular maintenance and inspection of both armoured cables and XLPE cables are essential to ensure their continued performance and longevity.

…

Periodic checks for signs of wear and tear, damage, or corrosion can help identify potential issues before they escalate into more significant problems, ultimately prolonging the lifespan of the cables and promoting optimal efficiency in the electrical system. When it comes to making a decision on whether to choose armoured cables or XLPE cables for a particular project, it is crucial to conduct a thorough evaluation of the technical specifications, environmental conditions, installation requirements, and budget constraints. By weighing these factors carefully and considering the unique advantages and characteristics of each type of cable, you can make an informed decision that aligns with the goals and objectives of the project. Ultimately, both armoured cables and XLPE cables play a vital role in the safe and efficient transmission of electricity across various industries and applications. Their unique properties, durability, and reliability make them indispensable components in power distribution systems, ensuring the seamless and uninterrupted flow of electrical energy to support a wide range of operations and functions. In conclusion, armoured cables and XLPE cables are both excellent choices for power transmission applications, each offering distinct advantages and benefits based on specific requirements. Whether prioritizing mechanical protection, high current-carrying capacity, temperature resistance, flexibility, or cost-effectiveness, there is a suitable cable option available to meet the diverse needs of different projects and installations. By understanding the key differences and features of armoured cables and XLPE cables, project managers, engineers, and installers can make well-informed decisions that optimize performance, reliability, and safety in electrical systems. The selection of the right cable type is essential in ensuring the success and efficiency of power distribution projects, enhancing overall operational effectiveness, and minimizing risks associated with electrical faults or failures. In conclusion, both armoured cables and XLPE cables have distinct advantages and applications, making them indispensable components in modern power distribution systems. By carefully assessing the specific requirements of a project and considering the unique characteristics of each cable type, stakeholders can make informed decisions that ensure optimal performance, safety, and efficiency in electrical installations and operations.

Periodic checks for signs of wear and tear, damage, or corrosion can help identify potential issues before they escalate into more significant problems, ultimately prolonging the lifespan of the cables and promoting optimal efficiency in the electrical system. When it comes to making a decision on whether to choose armoured cables or XLPE cables for a particular project, it is crucial to conduct a thorough evaluation of the technical specifications, environmental conditions, installation requirements, and budget constraints. By weighing these factors carefully and considering the unique advantages and characteristics of each type of cable, you can make an informed decision that aligns with the goals and objectives of the project. Ultimately, both armoured cables and XLPE cables play a vital role in the safe and efficient transmission of electricity across various industries and applications. Their unique properties, durability, and reliability make them indispensable components in power distribution systems, ensuring the seamless and uninterrupted flow of electrical energy to support a wide range of operations and functions. In conclusion, armoured cables and XLPE cables are both excellent choices for power transmission applications, each offering distinct advantages and benefits based on specific requirements. Whether prioritizing mechanical protection, high current-carrying capacity, temperature resistance, flexibility, or cost-effectiveness, there is a suitable cable option available to meet the diverse needs of different projects and installations. By understanding the key differences and features of armoured cables and XLPE cables, project managers, engineers, and installers can make well-informed decisions that optimize performance, reliability, and safety in electrical systems. The selection of the right cable type is essential in ensuring the success and efficiency of power distribution projects, enhancing overall operational effectiveness, and minimizing risks associated with electrical faults or failures. In conclusion, both armoured cables and XLPE cables have distinct advantages and applications, making them indispensable components in modern power distribution systems. By carefully assessing the specific requirements of a project and considering the unique characteristics of each cable type, stakeholders can make informed decisions that ensure optimal performance, safety, and efficiency in electrical installations and operations.

Your comment submitted.