Traditionally, copper conductors are used in power transmission cables, but the use of aluminum as a conductor has had a great impact on the price of these cables and will reduce the price of wire cables, but do aluminum cables have any other advantages other than a cheaper price? have?

Do they cope well with the task of transferring current or in what cases can these cables be used? In this article, we will introduce you to the types of aluminum wire cables, their uses and benefits.

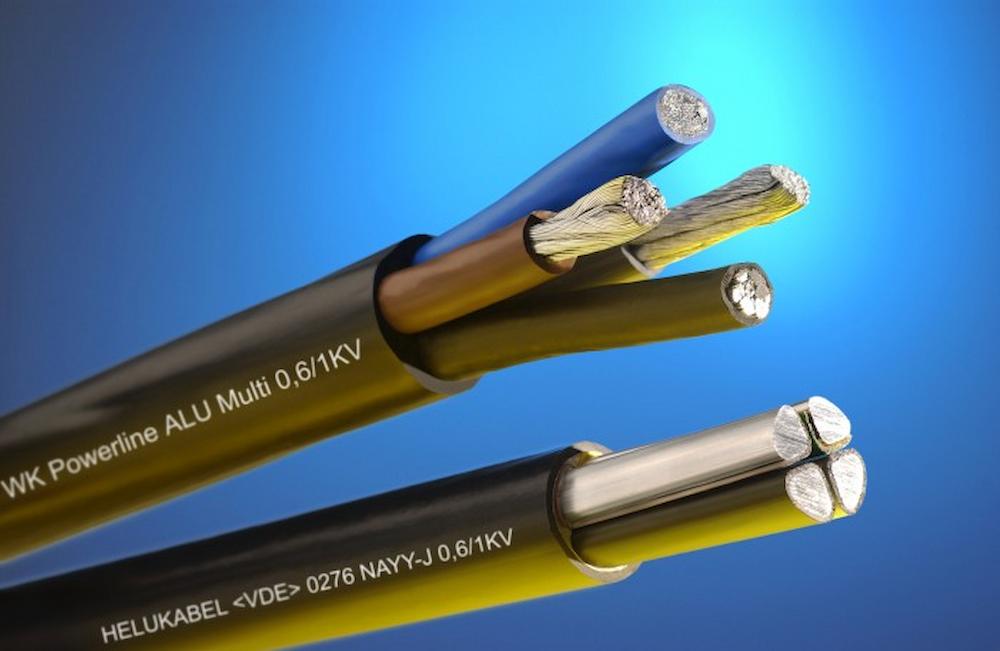

The most important feature of the aluminum wire cable is the same as its name: its conductors are aluminum, and not copper, its history of using these cables up to the 1880s and back to the United States, starting to use these cables on the railroad due to the damaging effect of locomotive smoke on the cables, the railway authorities thought that by destroying the copper cables were replaced by aluminum to a few meters long and trying to test its effect, they realized that after passing the aluminum smoke path, the aluminum material was coated against the aluminum oxide film actions. Types of Aluminum Cables: 1- Ground Aluminum Cable: These cables are used to bypass the electric current through hidden paths such as inside the walls of buildings, underground, or even on the walls, in fact these cables are designed so that they have to be placed in a fixed and unmoved location, so they are not suitable for passing through the air without a prop. The structure of these cables is composed of 6 parts, the first and the outermost part of the sheath cable, which protects the cable from moisture, the second part or the screen installed in the cable to discharge error currents, the third part is the insulating layer of the electric current which is normally used in transmission of normal voltages of PVC, the fourth part is the filler which fills the gap between the wire handles, the fifth or semi-conductor layer, and finally the sixth part which is electric conductor and consists of copper and aluminum tubes.

The ground cables are divided into two types of belt and pressure cables in their material and structure, and the ground cables are classified in size in four categories: single core, double core, three core and three and half nuclear, the ground cables are often installed in places where high impact and pressure tolerance is required, these cables are electrically resistant and resistant to external factors. 2- Aluminum Air Cable: In the electrical transmission paths of electrical poles, aluminum cables are used because their metamorphosis is very high and the use of aluminum as a conductor is much more economical, the only thing to be observed about the aluminum wire conductor is its cross section compared to the copper wire cable. In the same voltage transfer of the aluminum wire cable, it must have more cross-section area than copper wire cable to show the same performance as copper wire. The aerial aluminum wire cables are arranged in three categories of ACC cables (for medium or low-unannealed voltages transmission), AAAC (alloy and used for transmission of voltages and relatively high), and ACSR (unannealed and for transmission of high voltage current). 3- Controlled Aluminum Cable: These are equipped with a kind of armor and buried in the ground and outside of the facilities, in these cables the protective layer of XLPE is used, which is more durable than PVC to the blows, so these cables are used more in places where there is a greater chance of pressure and impact. 4- Self-sustaining aluminum cable: Special shielding operations used in this category of cables will increase the overall performance of the cable and use these cables to transfer electricity from the post to various domestic, agricultural and etc. systems so these cables can transfer single phase and three phase currents.

Specifications and price of aluminum wire cable

In the wide field of electrical current transmission, what is very important is the price of the conductor cable of electricity and the price of the cable depends naturally on the type of wire used in it. The conductor of the electrical current of both aluminum and copper can be that the price of the aluminum wire is lower and much more cost effective at the larj scale. Do the Aluminum and Copper wire have any differences in the quality of electrical current transmission? In general, what difference do these two sexes have in the elteric conductivity? Difference between Copper and Aluminum conductor: 1- The electrical resistance of aluminum wire is higher than that of copper wire. 2- The convenience of electrical conductivity in copper is more than aluminum. 3- Copper is more expensive than aluminum. 4- In open spaces where there is a risk of cable theft, better use of aluminum cable. 5- The weight of aluminum rod in a specified size is less than that of copper wire. 6- Due to the brittle nature of aluminum, this type of material cannot be used in the stack of maple cables. 7- Energy losses in aluminum cables are higher than copper. Given the seventh case, which refers to higher energy losses in aluminum cables, this level of energy loss can be ignored if one considers the risk of stealing outdoor copper cables and their high price on a large scale.

The price of aluminum wire cable in different types with special discount

As mentioned before, the use of cable with aluminum wire in open spaces and for the transmission of electric current with weak, medium, strong and very high pressure is used due to the lower price and the elimination of the risk of theft. It will be much more economical, only by increasing the cross-sectional area compared to copper wire, the transmission power of these cables can be brought closer to the cables with copper wire.

You can get cables with aluminum wire in different types of high quality from us, to buy different types of cables, contact our consultants in the support section of the website, and after receiving detailed guidance and advice, make a purchase, to communicate with Site consultants, just fill out the consultation request form inside the site.

Your comment submitted.