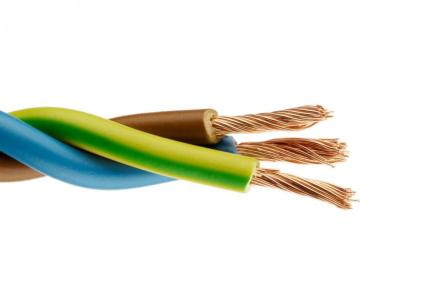

Copper wire is a versatile and essential component in various industries, known for its conductivity and durability. However, when it comes to specific applications that require additional protection against environmental factors or electrical insulation, varnished copper wire emerges as a superior choice. Varnished copper wire, also known as enameled copper wire, is a copper wire coated with a thin layer of insulation material, typically a varnish or enamel. This protective layer provides the wire with enhanced insulation properties while preserving its inherent conductivity. In this article, we delve into the characteristics, advantages, and applications of varnished copper wire to highlight why it is a crucial material in modern industries. One of the key characteristics that sets varnished copper wire apart from traditional copper wire is its insulation properties. The thin layer of varnish or enamel coating applied to the copper wire serves as an effective insulator, preventing the risk of short circuits or electrical breakdown. This insulation is especially important in applications where the copper wire is exposed to harsh environmental conditions, high voltages, or tight spaces where the risk of contact with other conductive materials is elevated. By providing a protective barrier around the copper wire, the varnish ensures reliable and safe operation in various electrical and electronic systems. Another notable advantage of varnished copper wire is its resistance to corrosion. Copper itself is prone to oxidation when exposed to moisture and corrosive elements, leading to a degradation in its electrical conductivity over time. The varnish coating on varnished copper wire acts as a shield against these corrosive agents, preserving the integrity of the copper wire and extending its lifespan. This corrosion resistance makes varnished copper wire ideal for outdoor applications, humid environments, and industrial settings where exposure to moisture or chemicals is a concern. Furthermore, varnished copper wire offers excellent thermal stability, making it suitable for applications that involve high temperatures. The insulation layer of varnish or enamel is designed to withstand elevated temperatures without compromising its insulating properties, ensuring that the copper wire remains stable and reliable even in demanding thermal conditions. This thermal stability is crucial in industries such as automotive, aerospace, and power generation, where components are subjected to extreme heat during operation. In terms of electrical properties, varnished copper wire exhibits low dielectric loss and high insulation resistance, contributing to optimal electrical performance in various applications. The insulation provided by the varnish layer minimizes energy losses and improves the efficiency of electrical systems utilizing varnished copper wire. Additionally, the high insulation resistance helps prevent leakage currents and ensures the integrity of electrical circuits, enhancing the overall reliability of the system. The versatility of varnished copper wire extends to its compatibility with different winding techniques and coil configurations. Due to its flexibility and insulation properties, varnished copper wire can be easily wound into coils of various shapes and sizes, making it suitable for custom applications that require specific coil designs. This flexibility in coil winding allows for greater design freedom and customization in electrical and electronic devices, resulting in optimized performance and space utilization.

.

The applications of varnished copper wire span across a wide range of industries, from electronics and telecommunications to automotive and industrial machinery. In the electronics sector, varnished copper wire is used in the production of transformers, motors, solenoids, and other electromagnetic components where efficient electrical insulation is essential. The superior insulation properties of varnished copper wire ensure reliable performance and longevity in these critical applications. In the automotive industry, varnished copper wire is employed in the manufacturing of ignition coils, sensors, actuators, and various electrical systems in vehicles. The corrosion resistance and thermal stability of varnished copper wire make it an ideal choice for automotive applications where durability and performance under extreme conditions are paramount. The use of varnished copper wire contributes to the overall efficiency and reliability of automotive electronic systems, improving the driving experience and vehicle safety. In the field of telecommunications, varnished copper wire plays a vital role in the production of high-frequency coils, inductors, and transformers used in telecommunications equipment. The insulation properties of varnished copper wire enable the transmission of signals with minimal interference, ensuring clear communication and data transfer in telecommunication networks. The reliability and quality of varnished copper wire contribute to the seamless operation of telecommunications infrastructure, supporting modern communication technologies and connectivity. In industrial machinery and power generation applications, varnished copper wire is utilized in motors, generators, transformers, and other electrical equipment that require robust insulation and high performance. The thermal stability and electrical properties of varnished copper wire make it a preferred choice for powering industrial machinery and generating electricity in power plants.

The applications of varnished copper wire span across a wide range of industries, from electronics and telecommunications to automotive and industrial machinery. In the electronics sector, varnished copper wire is used in the production of transformers, motors, solenoids, and other electromagnetic components where efficient electrical insulation is essential. The superior insulation properties of varnished copper wire ensure reliable performance and longevity in these critical applications. In the automotive industry, varnished copper wire is employed in the manufacturing of ignition coils, sensors, actuators, and various electrical systems in vehicles. The corrosion resistance and thermal stability of varnished copper wire make it an ideal choice for automotive applications where durability and performance under extreme conditions are paramount. The use of varnished copper wire contributes to the overall efficiency and reliability of automotive electronic systems, improving the driving experience and vehicle safety. In the field of telecommunications, varnished copper wire plays a vital role in the production of high-frequency coils, inductors, and transformers used in telecommunications equipment. The insulation properties of varnished copper wire enable the transmission of signals with minimal interference, ensuring clear communication and data transfer in telecommunication networks. The reliability and quality of varnished copper wire contribute to the seamless operation of telecommunications infrastructure, supporting modern communication technologies and connectivity. In industrial machinery and power generation applications, varnished copper wire is utilized in motors, generators, transformers, and other electrical equipment that require robust insulation and high performance. The thermal stability and electrical properties of varnished copper wire make it a preferred choice for powering industrial machinery and generating electricity in power plants.

..

The efficiency and durability of varnished copper wire contribute to sustainable energy production and reliable operation of industrial equipment, facilitating productivity and innovation in various sectors. Overall, varnished copper wire stands out as a critical component in modern industries due to its insulation properties, corrosion resistance, thermal stability, electrical performance, and versatility in applications. Whether used in electronics, automotive, telecommunications, or industrial machinery, varnished copper wire plays a significant role in enabling the efficient and reliable operation of electrical and electronic systems. With its combination of superior characteristics and wide-ranging benefits, varnished copper wire is a valuable material that continues to drive innovation and progress across diverse industries. The adoption of varnished copper wire in various industries is a testament to its exceptional properties and performance, highlighting its importance as a fundamental component in today’s technological landscape. As industries continue to evolve and advance, the demand for reliable, energy-efficient, and durable electrical solutions grows, placing varnished copper wire at the forefront of innovation and development. In the realm of renewable energy, varnished copper wire plays a crucial role in the production of wind turbines, solar panels, and energy storage systems. The sustainable nature of renewable energy sources requires components that can withstand environmental stresses and deliver consistent performance over extended periods. Varnished copper wire, with its insulation properties and corrosion resistance, provides the reliability and efficiency needed to harness renewable energy and contribute to a greener, more sustainable future. The aerospace industry also relies on varnished copper wire for its electrical systems and components, where lightweight materials with high performance are essential. The insulation and thermal properties of varnished copper wire make it an ideal choice for aircraft wiring, avionics, communication systems, and electrical subsystems. The ability of varnished copper wire to maintain its integrity in challenging aviation environments demonstrates its versatility and adaptability to stringent requirements in aerospace applications.

The efficiency and durability of varnished copper wire contribute to sustainable energy production and reliable operation of industrial equipment, facilitating productivity and innovation in various sectors. Overall, varnished copper wire stands out as a critical component in modern industries due to its insulation properties, corrosion resistance, thermal stability, electrical performance, and versatility in applications. Whether used in electronics, automotive, telecommunications, or industrial machinery, varnished copper wire plays a significant role in enabling the efficient and reliable operation of electrical and electronic systems. With its combination of superior characteristics and wide-ranging benefits, varnished copper wire is a valuable material that continues to drive innovation and progress across diverse industries. The adoption of varnished copper wire in various industries is a testament to its exceptional properties and performance, highlighting its importance as a fundamental component in today’s technological landscape. As industries continue to evolve and advance, the demand for reliable, energy-efficient, and durable electrical solutions grows, placing varnished copper wire at the forefront of innovation and development. In the realm of renewable energy, varnished copper wire plays a crucial role in the production of wind turbines, solar panels, and energy storage systems. The sustainable nature of renewable energy sources requires components that can withstand environmental stresses and deliver consistent performance over extended periods. Varnished copper wire, with its insulation properties and corrosion resistance, provides the reliability and efficiency needed to harness renewable energy and contribute to a greener, more sustainable future. The aerospace industry also relies on varnished copper wire for its electrical systems and components, where lightweight materials with high performance are essential. The insulation and thermal properties of varnished copper wire make it an ideal choice for aircraft wiring, avionics, communication systems, and electrical subsystems. The ability of varnished copper wire to maintain its integrity in challenging aviation environments demonstrates its versatility and adaptability to stringent requirements in aerospace applications.

…

Furthermore, the medical sector benefits from the use of varnished copper wire in a wide range of medical devices, diagnostic equipment, and healthcare systems. The insulation properties and biocompatibility of varnished copper wire make it a safe and reliable material for critical medical applications, such as imaging systems, surgical instruments, pacemakers, and implantable devices. The superior electrical performance of varnished copper wire ensures accurate and precise operation in medical settings, contributing to advances in healthcare technology and patient care. The emergence of smart technologies and the Internet of Things (IoT) has driven the demand for advanced sensors, actuators, and interconnected devices that rely on efficient electrical components. Varnished copper wire plays a key role in enabling the functionality and connectivity of smart devices, wearables, home automation systems, and IoT infrastructure. The insulation and electrical properties of varnished copper wire support the seamless integration of sensors and electronic components into smart applications, enhancing automation, monitoring, and control capabilities in various environments. In the realm of research and development, varnished copper wire is utilized in scientific instruments, laboratory equipment, and experimental setups that require precise electrical conduction and insulation. The reliability and performance of varnished copper wire contribute to the accuracy and reproducibility of scientific experiments, measurements, and analyses across disciplines such as physics, chemistry, biology, and engineering. The versatility and consistency of varnished copper wire make it a valuable resource for researchers and innovators seeking reliable electrical solutions in their work. As businesses and industries strive to enhance their technological capabilities, the choice of high-quality materials such as varnished copper wire becomes paramount in achieving optimal performance, efficiency, and reliability in electrical and electronic systems. The unique properties of varnished copper wire make it a preferred material for a wide range of applications that demand exceptional insulation, corrosion resistance, thermal stability, and electrical performance. In conclusion, varnished copper wire stands as a foundational material that continues to drive progress, innovation, and sustainability in diverse industries and sectors. Its versatility, durability, and performance make it an indispensable component in modern electrical and electronic systems, supporting advancements in technology, communication, energy, healthcare, aerospace, and beyond. By harnessing the benefits of varnished copper wire, businesses and industries can ensure the efficient and reliable operation of their devices, equipment, and infrastructure, paving the way for a future fueled by connectivity, efficiency, and progress.

Furthermore, the medical sector benefits from the use of varnished copper wire in a wide range of medical devices, diagnostic equipment, and healthcare systems. The insulation properties and biocompatibility of varnished copper wire make it a safe and reliable material for critical medical applications, such as imaging systems, surgical instruments, pacemakers, and implantable devices. The superior electrical performance of varnished copper wire ensures accurate and precise operation in medical settings, contributing to advances in healthcare technology and patient care. The emergence of smart technologies and the Internet of Things (IoT) has driven the demand for advanced sensors, actuators, and interconnected devices that rely on efficient electrical components. Varnished copper wire plays a key role in enabling the functionality and connectivity of smart devices, wearables, home automation systems, and IoT infrastructure. The insulation and electrical properties of varnished copper wire support the seamless integration of sensors and electronic components into smart applications, enhancing automation, monitoring, and control capabilities in various environments. In the realm of research and development, varnished copper wire is utilized in scientific instruments, laboratory equipment, and experimental setups that require precise electrical conduction and insulation. The reliability and performance of varnished copper wire contribute to the accuracy and reproducibility of scientific experiments, measurements, and analyses across disciplines such as physics, chemistry, biology, and engineering. The versatility and consistency of varnished copper wire make it a valuable resource for researchers and innovators seeking reliable electrical solutions in their work. As businesses and industries strive to enhance their technological capabilities, the choice of high-quality materials such as varnished copper wire becomes paramount in achieving optimal performance, efficiency, and reliability in electrical and electronic systems. The unique properties of varnished copper wire make it a preferred material for a wide range of applications that demand exceptional insulation, corrosion resistance, thermal stability, and electrical performance. In conclusion, varnished copper wire stands as a foundational material that continues to drive progress, innovation, and sustainability in diverse industries and sectors. Its versatility, durability, and performance make it an indispensable component in modern electrical and electronic systems, supporting advancements in technology, communication, energy, healthcare, aerospace, and beyond. By harnessing the benefits of varnished copper wire, businesses and industries can ensure the efficient and reliable operation of their devices, equipment, and infrastructure, paving the way for a future fueled by connectivity, efficiency, and progress.

Your comment submitted.