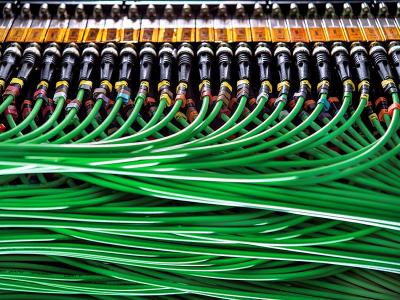

XLPE armoured cables are an essential component in various industries and applications where a high level of electrical performance and durability is required. The term “XLPE” stands for Cross-linked Polyethylene, which refers to the insulation material used in these cables. The addition of armor provides extra protection, making them suitable for a wide range of demanding environments. In this comprehensive guide, we will delve into the full form, specifications, and applications of XLPE armoured cables to help you make an informed decision when selecting cables for your projects. Full Form of XLPE Armoured Cable XLPE armoured cable comprises three key components: Cross-linked Polyethylene (XLPE), Armoured, and Cable. 1. Cross-linked Polyethylene (XLPE): XLPE is a type of thermosetting polymer that offers superior electrical and mechanical properties compared to traditional PVC insulation. The cross-linking process enhances the temperature rating, voltage capability, and resistance to environmental factors such as moisture, heat, and chemicals.

.

XLPE insulation is renowned for its excellent insulation resistance, low dielectric losses, and long-term performance. 2. Armoured: The term “armoured” refers to the protective layer surrounding the conductors within the cable. Armoring provides mechanical protection against external impacts, crushing forces, and rodent attacks. Common types of armoring include steel wire armoring (SWA) and steel tape armoring (STA), which enhance the cable’s robustness and resistance to external stresses. 3. Cable: The term “cable” refers to the complete assembly of components, including conductors, insulation, armoring, and sheathing. XLPE armoured cables are designed to transmit electrical power efficiently and safely, making them essential for various industrial, commercial, and residential applications. Specifications of XLPE Armoured Cables XLPE armoured cables are available in a wide range of configurations to suit different voltage ratings, conductor sizes, armor types, and sheath materials. When selecting XLPE armoured cables for your project, consider the following key specifications: 1. Voltage Rating: XLPE armoured cables are manufactured for different voltage applications, ranging from low voltage (LV) to medium voltage (MV) and high voltage (HV). The voltage rating determines the cable’s insulation thickness, conductivity, and performance characteristics. 2. Conductor Size: The conductor size, typically measured in square millimeters (mm²), determines the current-carrying capacity and electrical resistance of the cable. Choose the appropriate conductor size based on the current load and voltage drop requirements of your installation. 3. Armoring Type: XLPE armoured cables can be armored with steel wire (SWA) or steel tape (STA) to provide mechanical protection and enhanced tensile strength. The choice of armoring type depends on the application environment, installation method, and protection requirements. 4. Insulation Material: XLPE insulation offers superior electrical properties, thermal stability, and moisture resistance compared to PVC insulation. XLPE armoured cables are suitable for both indoor and outdoor installations, providing reliable performance in challenging conditions.

XLPE insulation is renowned for its excellent insulation resistance, low dielectric losses, and long-term performance. 2. Armoured: The term “armoured” refers to the protective layer surrounding the conductors within the cable. Armoring provides mechanical protection against external impacts, crushing forces, and rodent attacks. Common types of armoring include steel wire armoring (SWA) and steel tape armoring (STA), which enhance the cable’s robustness and resistance to external stresses. 3. Cable: The term “cable” refers to the complete assembly of components, including conductors, insulation, armoring, and sheathing. XLPE armoured cables are designed to transmit electrical power efficiently and safely, making them essential for various industrial, commercial, and residential applications. Specifications of XLPE Armoured Cables XLPE armoured cables are available in a wide range of configurations to suit different voltage ratings, conductor sizes, armor types, and sheath materials. When selecting XLPE armoured cables for your project, consider the following key specifications: 1. Voltage Rating: XLPE armoured cables are manufactured for different voltage applications, ranging from low voltage (LV) to medium voltage (MV) and high voltage (HV). The voltage rating determines the cable’s insulation thickness, conductivity, and performance characteristics. 2. Conductor Size: The conductor size, typically measured in square millimeters (mm²), determines the current-carrying capacity and electrical resistance of the cable. Choose the appropriate conductor size based on the current load and voltage drop requirements of your installation. 3. Armoring Type: XLPE armoured cables can be armored with steel wire (SWA) or steel tape (STA) to provide mechanical protection and enhanced tensile strength. The choice of armoring type depends on the application environment, installation method, and protection requirements. 4. Insulation Material: XLPE insulation offers superior electrical properties, thermal stability, and moisture resistance compared to PVC insulation. XLPE armoured cables are suitable for both indoor and outdoor installations, providing reliable performance in challenging conditions.

..

5. Sheath Material: The outer sheath material of XLPE armoured cables can be made of PVC, polyethylene, or LSZH (Low Smoke Zero Halogen) for additional protection against environmental factors, UV radiation, and flame propagation. The sheath material enhances the cable’s durability and longevity in harsh environments. Applications of XLPE Armoured Cables XLPE armoured cables are widely used in various industries and applications due to their superior electrical performance, mechanical strength, and environmental resistance. Some common applications of XLPE armoured cables include: 1. Power Distribution: XLPE armoured cables are used for transmitting electrical power in underground installations, industrial plants, utilities, and high-voltage substations. The armored construction protects the cables from external damage and ensures reliable power distribution. 2. Construction Projects: XLPE armoured cables are ideal for construction sites, building complexes, and infrastructure projects where robust electrical cables are required. The armor provides physical protection against construction activities, concrete pour, and accidental damage. 3. Oil and Gas Industry: XLPE armoured cables are commonly used in the oil and gas industry for powering drilling rigs, offshore platforms, refineries, and petrochemical plants. The cables are designed to withstand harsh environments, chemical exposure, and temperature fluctuations. 4. Renewable Energy: XLPE armoured cables play a crucial role in renewable energy projects such as solar farms, wind turbines, and hydroelectric plants. The cables deliver reliable power transmission from renewable sources to the grid, supporting the transition to clean energy. 5. Rail and Transportation: XLPE armoured cables are essential for rail and transportation infrastructure, including metro systems, railways, and airports. The cables provide safe and efficient power supply for signaling, communication, lighting, and traction systems. In conclusion, XLPE armoured cables offer a reliable and durable solution for a wide range of electrical installations requiring high-performance cables. The cross-linked polyethylene insulation and armored construction make these cables suitable for demanding environments where protection, longevity, and safety are paramount.

5. Sheath Material: The outer sheath material of XLPE armoured cables can be made of PVC, polyethylene, or LSZH (Low Smoke Zero Halogen) for additional protection against environmental factors, UV radiation, and flame propagation. The sheath material enhances the cable’s durability and longevity in harsh environments. Applications of XLPE Armoured Cables XLPE armoured cables are widely used in various industries and applications due to their superior electrical performance, mechanical strength, and environmental resistance. Some common applications of XLPE armoured cables include: 1. Power Distribution: XLPE armoured cables are used for transmitting electrical power in underground installations, industrial plants, utilities, and high-voltage substations. The armored construction protects the cables from external damage and ensures reliable power distribution. 2. Construction Projects: XLPE armoured cables are ideal for construction sites, building complexes, and infrastructure projects where robust electrical cables are required. The armor provides physical protection against construction activities, concrete pour, and accidental damage. 3. Oil and Gas Industry: XLPE armoured cables are commonly used in the oil and gas industry for powering drilling rigs, offshore platforms, refineries, and petrochemical plants. The cables are designed to withstand harsh environments, chemical exposure, and temperature fluctuations. 4. Renewable Energy: XLPE armoured cables play a crucial role in renewable energy projects such as solar farms, wind turbines, and hydroelectric plants. The cables deliver reliable power transmission from renewable sources to the grid, supporting the transition to clean energy. 5. Rail and Transportation: XLPE armoured cables are essential for rail and transportation infrastructure, including metro systems, railways, and airports. The cables provide safe and efficient power supply for signaling, communication, lighting, and traction systems. In conclusion, XLPE armoured cables offer a reliable and durable solution for a wide range of electrical installations requiring high-performance cables. The cross-linked polyethylene insulation and armored construction make these cables suitable for demanding environments where protection, longevity, and safety are paramount.

…

By understanding the full form, specifications, and applications of XLPE armoured cables, you can select the most appropriate cables for your projects and ensure optimal performance and reliability. XLPE armoured cables are a critical component in modern electrical systems, providing a safe and efficient means of power transmission in diverse industries and applications. Whether you are involved in power distribution, construction projects, oil and gas operations, renewable energy initiatives, or transportation infrastructure, choosing the right XLPE armoured cable can significantly impact the performance and longevity of your electrical installations. When selecting XLPE armoured cables for your project, it is essential to consider the specific requirements and environmental conditions in which the cables will be installed. Factors such as voltage rating, conductor size, armoring type, insulation material, and sheath material play a crucial role in determining the suitability of the cables for your application. By working with reputable suppliers and manufacturers who offer a wide range of XLPE armoured cables with varying specifications, you can ensure that you have the right cables for your needs. One of the key advantages of XLPE armoured cables is their durability and resistance to external factors such as moisture, heat, chemicals, and mechanical stress. The cross-linked polyethylene insulation provides excellent insulation properties, ensuring reliable electrical performance even in challenging environments. The armoring adds an extra layer of protection against physical damage and ensures the integrity of the cables over the long term. In addition to their technical specifications, XLPE armoured cables also offer cost-effective solutions for electrical installations that require high performance and reliability. The long service life, low maintenance requirements, and robust construction of XLPE armoured cables make them a preferred choice for many industries seeking to optimize their electrical systems. In conclusion, XLPE armoured cables are essential components of electrical systems that require high levels of performance, reliability, and safety. By understanding the full form, specifications, and applications of XLPE armoured cables, you can make informed decisions when selecting cables for your projects. Whether you are involved in power distribution, construction, oil and gas, renewable energy, or transportation, investing in high-quality XLPE armoured cables will ensure the success and longevity of your electrical installations. Choose XLPE armoured cables for their superior performance, durability, and versatility in meeting the demanding requirements of modern electrical systems.

By understanding the full form, specifications, and applications of XLPE armoured cables, you can select the most appropriate cables for your projects and ensure optimal performance and reliability. XLPE armoured cables are a critical component in modern electrical systems, providing a safe and efficient means of power transmission in diverse industries and applications. Whether you are involved in power distribution, construction projects, oil and gas operations, renewable energy initiatives, or transportation infrastructure, choosing the right XLPE armoured cable can significantly impact the performance and longevity of your electrical installations. When selecting XLPE armoured cables for your project, it is essential to consider the specific requirements and environmental conditions in which the cables will be installed. Factors such as voltage rating, conductor size, armoring type, insulation material, and sheath material play a crucial role in determining the suitability of the cables for your application. By working with reputable suppliers and manufacturers who offer a wide range of XLPE armoured cables with varying specifications, you can ensure that you have the right cables for your needs. One of the key advantages of XLPE armoured cables is their durability and resistance to external factors such as moisture, heat, chemicals, and mechanical stress. The cross-linked polyethylene insulation provides excellent insulation properties, ensuring reliable electrical performance even in challenging environments. The armoring adds an extra layer of protection against physical damage and ensures the integrity of the cables over the long term. In addition to their technical specifications, XLPE armoured cables also offer cost-effective solutions for electrical installations that require high performance and reliability. The long service life, low maintenance requirements, and robust construction of XLPE armoured cables make them a preferred choice for many industries seeking to optimize their electrical systems. In conclusion, XLPE armoured cables are essential components of electrical systems that require high levels of performance, reliability, and safety. By understanding the full form, specifications, and applications of XLPE armoured cables, you can make informed decisions when selecting cables for your projects. Whether you are involved in power distribution, construction, oil and gas, renewable energy, or transportation, investing in high-quality XLPE armoured cables will ensure the success and longevity of your electrical installations. Choose XLPE armoured cables for their superior performance, durability, and versatility in meeting the demanding requirements of modern electrical systems.

Your comment submitted.