Due to the wide application of xlpe wire cable insulation composition, manufacturers of this material should always pay attention to the following points in order to provide the best quality products.

XLPE pipe is not a perfect solution, which is the most important fact to note. XLPE pipes have inherent hazards that must be considered during system construction. Improper installation and misuse can cause damage to XLPE pipes.

If installed improperly, they may crack or even break. Always make sure they are properly installed to avoid this. XLPE pipes are susceptible to abuse if over-torqued or over-bent. Avoid exceeding the recommended torque settings and turning radius. These two factors alone can cause significant financial damage.

Cross-linked polyethylene pipes are not resistant to corrosion. Corrosion occurs when oxidized metal parts come into contact with each other. Corrosion is caused by oxidation and causes the metal to lose its original quality and eventually perish.

When working with plastic pipes of any kind, it is essential to keep them clean. To clean the pipes, the complete washing of the pipes is used. You can use a pipe cleaner or soap and water. Do not use abrasive or harsh cleaning products or chemicals.

A pipe made of cross-linked polyethylene is highly flammable. XLPE pipes do not burn efficiently and are flammable. Always make sure any fires are out before leaving the area. Never smoke inside any plastic pipe while using it.

Extreme temperature fluctuations can destroy XLPE pipes. XLPE pipes are made of synthetic materials that expand and contract at different rates depending on temperature.

In cold temperature conditions, XLPE pipe expands faster than normal, and in hot weather conditions, it contracts faster than normal. If you live in an area that experiences extreme weather conditions, you should check your plumbing frequently.

Under pressure, the cross-linked polyethylene pipe splits or tears. XLPE pipes are prone to burst under high pressure. If you find a crack or tear in your XLPE pipe, you should immediately stop using the line until it is fixed. The best way to repair XLPE pipe is to replace it.

XLPE pipes cannot be welded. Since XLPE pipes are not made of steel, it is difficult and expensive to weld them together. Generally, welded XLPE pipes are used only for maintenance purposes.

Crossed polyethylene pipes are considered dangerous for animals. Animals can die if they get stuck in XLPE pipe. Avoid exposing dogs to XLPE pipes.

XLPE pipes are cumbersome. XLPE pipe can weigh hundreds of pounds. Be careful to handle it carefully.

XLPE pipe may leak. It is possible for XLPE pipes to leak due to manufacturing defects. If you notice a plumbing leak, call a plumber immediately.

XLPE pipe can be melted. XLPE pipe melts at approximately 300°F. If your XLPE pipe is melting, turn off the power immediately and call a professional.

XLPE pipes are expensive. XLPE pipe costs more than ordinary PVC pipe.

Pipe made of cross-linked polyethylene cannot be recycled. Once the XLPE pipe is discarded, it will no longer exist. There is no recycling method for XLPE pipe.

Crossed polyethylene pipes are harmful to health. XLPE pipes, like many polymers, contain phthalates and other hazardous chemicals. These types of pipes should be avoided as much as possible.

The cross-linked polyethylene pipe is fragile. XLPE pipes are very fragile and break easily. If this happens, immediately turn off the water supply and call a professional. If this problem occurs regularly, otherwise replace the plumbing.

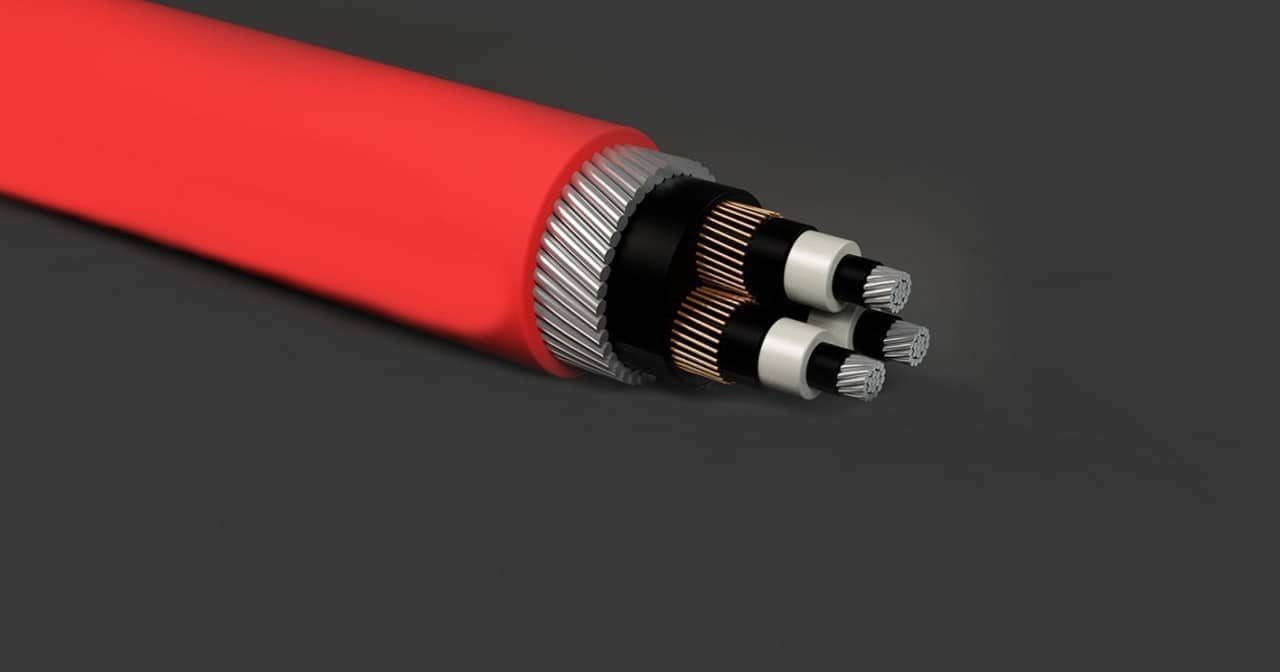

xlpe cable compound

The special properties of XLPE compound as cable insulation make it an ideal choice for cases where special qualities are expected.

XLPE insulation is often used to prevent moisture damage to cables. XLPE (cross-linked polyethylene) is a chemically and mechanically resistant polymer. In the temperature range of -200°F to +400°F (-129°C to +204°C), it has exceptional insulating properties. XLPE is resistant to corrosion, oxidation and chemicals. In addition to being non-conductive, it does not conduct electricity.

Since the 1970s, XLPE insulation has been widely used in the telecommunications industry. They were first launched in the 1960s. Due to its exceptional properties, XLPE insulations are now used in numerous industries including power transmission and distribution, oil and gas, mining, marine and heavy equipment, etc.

XLPE insulation can be applied manually or by automated processes such as injection molding, extrusion, and calendering.

Insulation made from XLPE is available in a wide range of thicknesses, lengths and diameters. 15″ to 100″ long and 0.015″ to 1.25″ diameter are standard sizes.

Insulation made of XLPE must be put in place first, before the cables are connected. If XLPE insulation is placed after the joint is completed, water leakage may cause the joint to fail. XLPE insulation must be buried at least 6 inches underground to prevent water infiltration.

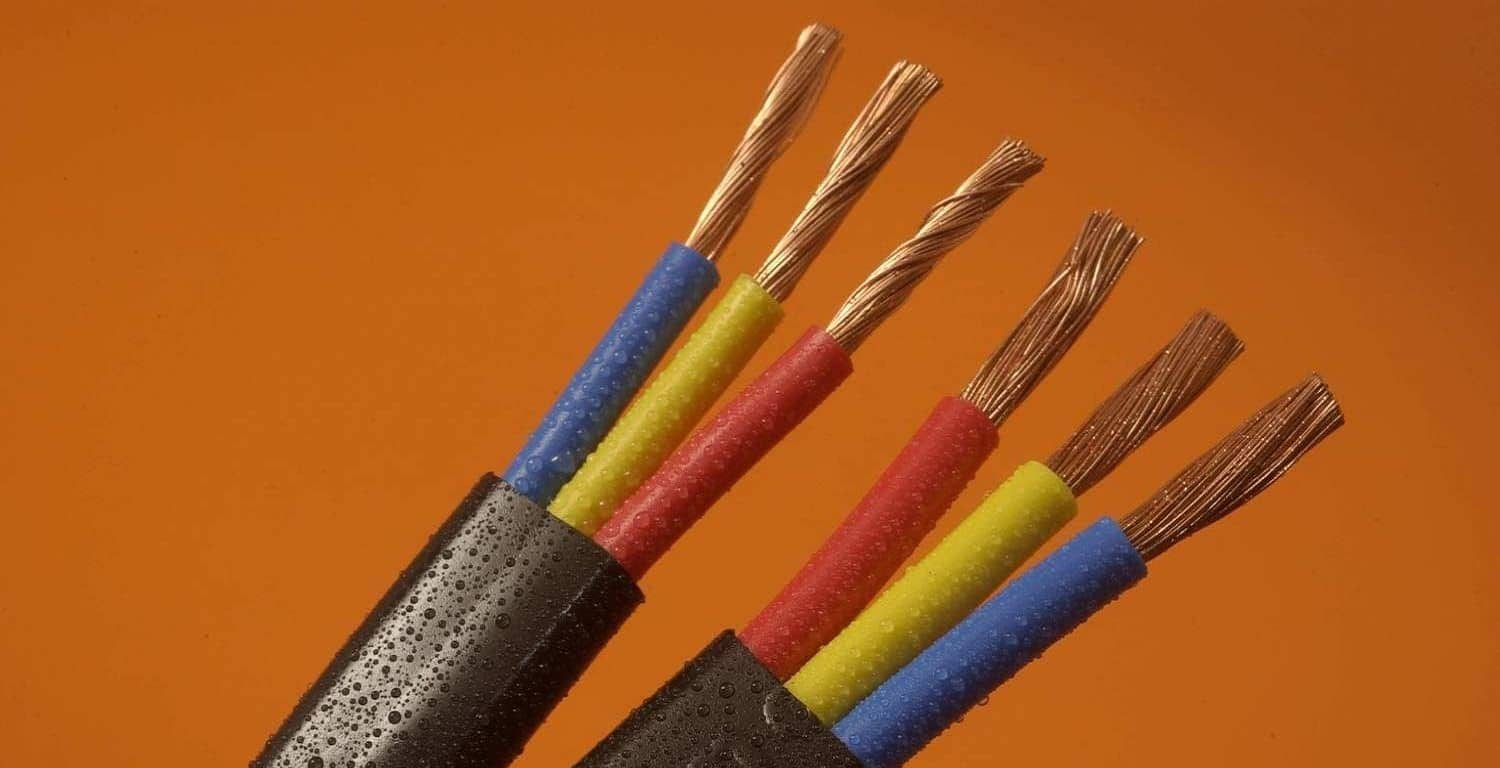

The insulated polyethylene wire cable is made of two layers of polyethylene that are laminated and cross-connected respectively. In most cases, the layer closest to the surface is white or gray. XLPE insulated cables may withstand voltages up to 1000V and have strong dielectric strength. Cables with XLPE insulation are adaptable and have a long life.

The insulation used in XLPE cables is made to withstand the harshest weather conditions without being damaged. However, it is strongly recommended that XLPE insulated wires be protected against the most extreme weather conditions.

XLPE insulation requires regular maintenance. Insulators made from XLPE are capable of functioning properly as long as they are routinely inspected and cleaned. Inspecting XLPE insulation for damage such as cracks, holes, tears, uneven surfaces, and large accumulations of dirt is an important step in proper cleaning. Manual dusting can be done with a wire brush or mechanically with a device called a duster.

A duster is a piece of machinery powered by motors and used to remove dirt and debris from surfaces.Wires insulated with XLPE should undergo routine checks to ensure that the insulation is as expected. During inspections, it is important to look for damaged insulation, loose connections, and exposed wires.

Your comment submitted.